Thermal shock is one of the most common causes of refractory failure in high-temperature furnaces. This case study examines how targeted refractory selection and system design significantly improved thermal shock resistance and operational stability in a demanding industrial furnace environment.

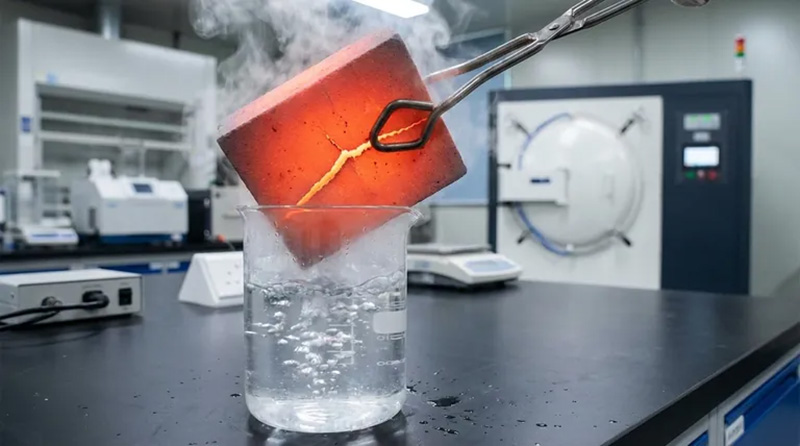

High-temperature furnaces used in steelmaking and metallurgical processing often operate under severe thermal cycling. Rapid heating and cooling during start-ups, shutdowns, and process fluctuations place extreme stress on refractory linings. In this case, an industrial furnace experienced frequent refractory cracking and spalling, leading to unplanned shutdowns and high maintenance costs.

Initial analysis showed that the existing lining material had adequate refractoriness but lacked sufficient thermal shock resistance. Microcracks formed during rapid temperature changes, gradually propagating into visible damage. Over time, this compromised the structural integrity of the lining and reduced campaign life.

The solution began with a detailed evaluation of operating conditions, including temperature gradients, heating rates, and mechanical constraints. Based on this analysis, the refractory system was redesigned using materials with improved thermal expansion compatibility and enhanced elasticity. High-purity alumina aggregates were combined with carefully selected bonding systems to improve crack resistance without sacrificing strength.

Attention was also given to lining design. Expansion allowances and joint placement were optimized to reduce stress concentration during thermal cycling. Installation practices were revised to ensure uniform compaction and controlled curing, eliminating weak points that could trigger failure.

After implementation, the furnace demonstrated a significant reduction in spalling and surface cracking. Thermal shock resistance improved noticeably, allowing the furnace to handle frequent temperature changes without lining damage. Campaign life increased, maintenance intervals were extended, and overall operational stability improved.

This case highlights that improving thermal shock resistance is not achieved through material selection alone. A combination of proper raw materials, system design, and installation discipline is essential for long-term success in high-temperature applications.

Pennekamp Middle East supports industrial operations with refractory solutions designed for demanding thermal conditions. Contact our team to improve thermal shock resistance in your furnace systems.