Introduction

In high-stress industrial environments, where temperatures soar and materials face extreme conditions, the choice of refractory materials is critical. Refractory plastics, also known as refractory castables or refractory mortars, are engineered to address these challenges with remarkable performance. This blog delves into the properties and advantages of refractory plastics, their applications in high-stress scenarios, and how they contribute to improved efficiency and durability in demanding industrial settings.

What Are Refractory Plastics?

Refractory plastics are advanced refractory materials that can be shaped and applied like a plastic material before curing. They are composed of a blend of high-temperature resistant aggregates, binders, and additives, designed to withstand severe conditions. Unlike traditional refractory bricks, refractory plastics are applied in a liquid or paste form, allowing for versatile use in complex geometries and high-stress areas.

Properties of Refractory Plastics

- High Temperature Resistance:

Refractory plastics can endure extremely high temperatures, making them suitable for applications where conventional materials might fail. They maintain structural integrity and performance under intense heat, making them ideal for furnaces, kilns, and reactors. - Thermal Shock Resistance:

These materials are designed to resist rapid temperature changes without cracking or spalling. This property is crucial for applications where frequent temperature fluctuations occur, ensuring the longevity and reliability of the refractory lining. - Mechanical Strength:

Refractory plastics exhibit high mechanical strength, which allows them to withstand mechanical stresses, abrasion, and impact. This strength is essential for applications subject to high stress and wear. - Chemical Resistance:

With resistance to corrosive chemicals, slags, and molten metals, refractory plastics protect underlying structures from chemical degradation. This resistance helps extend the life of equipment and reduces maintenance needs. - Ease of Application:

The paste-like consistency of refractory plastics allows for easy application and shaping. This versatility enables their use in complex and irregular geometries, reducing the need for custom-shaped bricks or tiles.

Benefits of Using Refractory Plastics

- Enhanced Durability:

Refractory plastics provide a robust lining solution that resists wear, corrosion, and thermal stress. Their durability contributes to a longer operational life for high-stress equipment, reducing the frequency of repairs and replacements. - Improved Efficiency:

By maintaining thermal stability and reducing heat loss, refractory plastics help improve the overall efficiency of industrial processes. This efficiency leads to lower energy consumption and operational costs. - Versatility in Application:

The ability to apply refractory plastics in various shapes and forms makes them suitable for a wide range of applications, including linings, repair work, and complex furnace components. - Reduced Downtime:

The ease of application and quick curing times of refractory plastics minimize downtime during maintenance and repairs. This efficiency helps maintain continuous operation and reduces production interruptions. - Cost-Effectiveness:

Although the initial cost of refractory plastics may be higher than some traditional materials, their durability and reduced maintenance requirements result in long-term cost savings.

Applications in High-Stress Environments

- Furnaces and Kilns:

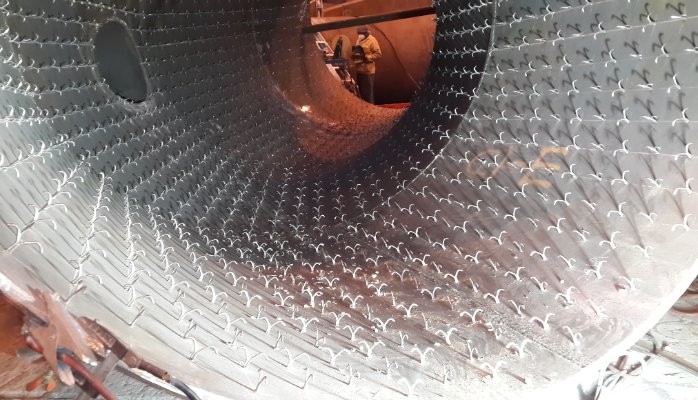

Refractory plastics are used to line the interiors of furnaces and kilns, where they endure high temperatures and aggressive conditions. Their ability to withstand thermal stress and chemical attack makes them ideal for these applications. - Industrial Reactors:

In industrial reactors, refractory plastics provide protection against corrosive substances and high temperatures. Their high mechanical strength and chemical resistance ensure the longevity and reliability of reactor linings. - Steelmaking:

The steelmaking process involves extreme temperatures and corrosive environments, making refractory plastics an excellent choice for ladles, converters, and other high-stress components. - Glass Production:

Refractory plastics are used in glass furnaces to maintain thermal stability and resist chemical attack from molten glass and other materials. - Petrochemical Processing:

In petrochemical processing, refractory plastics protect equipment from high temperatures and corrosive chemicals, ensuring the efficient operation of processing units.

Conclusion

Refractory plastics offer a versatile and high-performance solution for high-stress industrial applications. Their exceptional temperature resistance, thermal shock resistance, mechanical strength, and chemical resistance make them ideal for demanding environments. By enhancing durability, improving efficiency, and reducing downtime, refractory plastics contribute to the optimal performance and longevity of industrial equipment. At Pennekamp Middle East, we are dedicated to providing advanced refractory plastics tailored to meet the specific needs of your high-stress applications, ensuring superior performance and reliability in every operation.