In the design and selection of refractory materials, few factors are as critically important—and as potentially destructive—as the presence of alkaline compounds. For engineers and operators in high-temperature industries, alkalis are a formidable adversary. These chemical agents, often present in raw materials and fuels, can drastically shorten the service life of a furnace lining, leading to costly downtime and significant safety concerns.

However, dealing with alkalis is not simply a matter of avoidance; it’s a matter of strategic material design. Understanding the science behind alkali attack is the first step toward selecting and engineering refractories that can not only withstand but thrive in these harsh chemical environments.

The Mechanism of Alkali Attack: A Chemical Invasion

The primary culprits in alkali attack are potassium oxide (K₂O) and sodium oxide (Na₂O). These compounds typically volatilize at high temperatures, becoming aggressive vapors that penetrate the porous structure of refractory materials1. Once inside, a destructive chemical chain reaction begins:

- Penetration and Condensation: Alkali vapors seep into the pores of the refractory brick or castable and condense into a liquid phase within the material’s structure.

- Chemical Reaction: The condensed alkalis react with the primary components of the refractory, particularly free silica (SiO₂) and alumina (Al₂O₃)2.

- Formation of Low-Melting Point Liquids: This reaction forms new, complex alkali-alumino-silicate compounds3. Crucially, these new compounds have a much lower melting point than the original refractory material.

- Structural Degradation: The formation of this liquid phase weakens the refractory’s structural bond, drastically reducing its hot strength and load-bearing capacity4. This internal “fluxing” leads to softening, densification, and eventually, spalling and catastrophic failure of the lining.

Industries on the Front Line of Alkali Attack

While a concern in many processes, alkali attack is a particularly dominant failure mechanism in several key industries:

- The Cement Industry: The cement production process is a perfect storm for alkali attack. Alkalis present in the raw meal and fuels continuously circulate and concentrate within the kiln system, creating a highly aggressive environment for the refractory lining, especially in the transition and preheater zones.

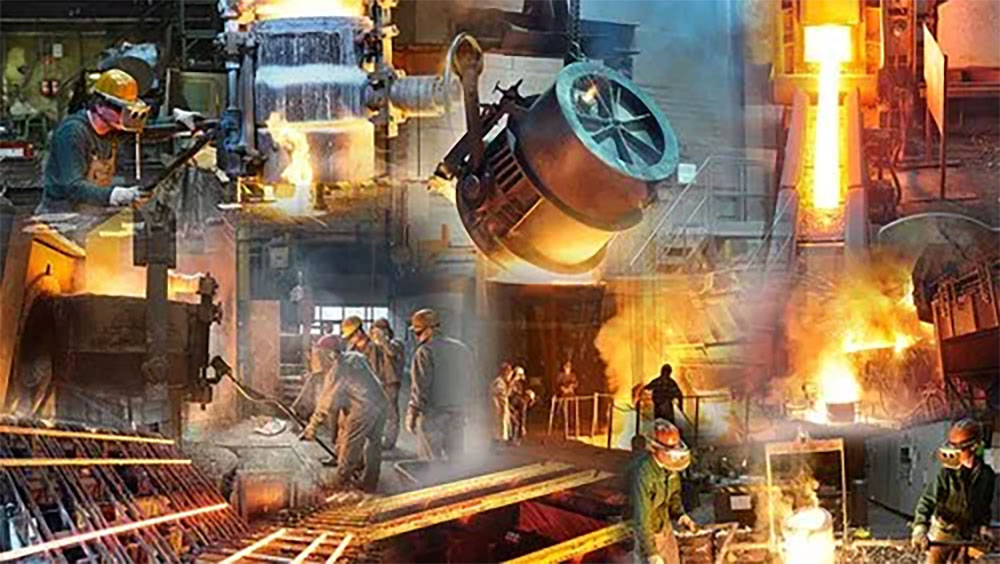

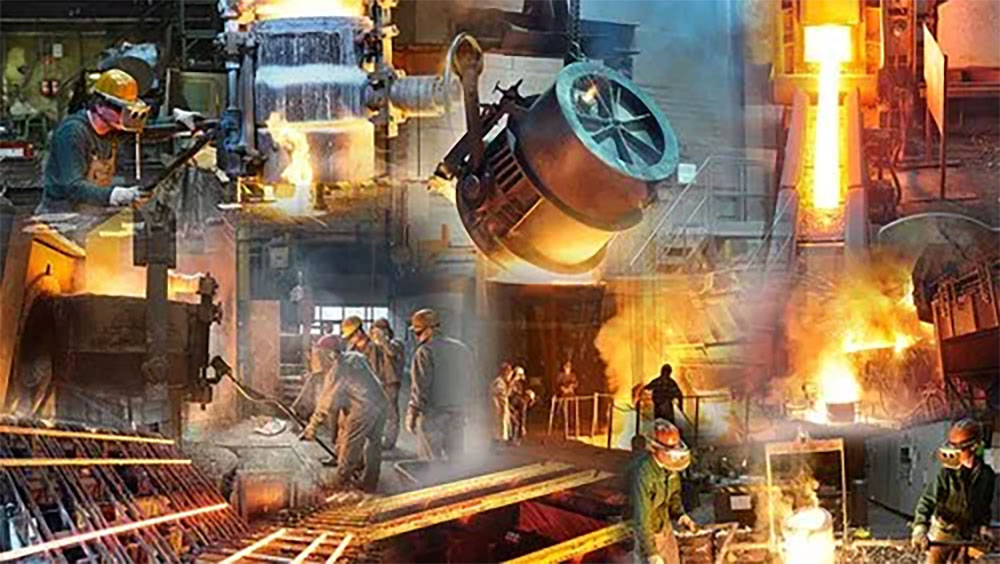

- The Iron & Steel Industry: In ironmaking blast furnaces, alkalis are introduced through coke and iron ore. Over time, they accumulate and attack the furnace’s aluminosilicate refractory stack lining, contributing significantly to wear and campaign length limitations5.

- Glass and Ceramics: In these industries, alkali compounds are often integral components of the product batch itself, meaning the furnace refractories are in constant, direct contact with these corrosive agents.

Designing for Defense: Advanced Refractory Solutions

Combating alkali attack requires intelligent refractory design that anticipates and counters the chemical mechanisms at play. The strategy revolves around using materials that are either inherently resistant or are engineered to prevent alkali penetration.

- High-Alumina Refractories: Materials with higher alumina content (typically 50% Al₂O₃ and above) generally exhibit better resistance to alkali attack than those with higher silica content.

- Low Porosity and High Density: A primary defense mechanism is to create a refractory body with very low porosity. By minimizing the number and size of pores, the material presents a much more difficult path for alkali vapors to penetrate, slowing the degradation process significantly.

- Strategic Use of Silicon Carbide (SiC): One of the most effective modern strategies is the addition of Silicon Carbide to alumina-based refractories. In an alkaline environment, the SiC oxidizes to form a highly viscous, glassy layer on the refractory surface6. This protective glaze effectively seals the pores, blocking further alkali infiltration and protecting the underlying material7.

The challenge of alkaline compounds underscores the importance of a scientific, application-specific approach to refractory selection. A solution that works in one process may not work in another, making deep material expertise an invaluable asset.

Fortify Your Operations Against Alkali Attack

At Pennekamp Middle East, we understand the complex chemistry of high-temperature industrial processes. Our comprehensive portfolio includes advanced, engineered refractories specifically designed to resist chemical attack from alkaline compounds, ensuring greater reliability and longer service life for your critical assets.

Contact our technical experts today to discuss your specific operational challenges and discover how our tailored refractory solutions can protect your investment.