Have you ever wondered what keeps furnaces, kilns, and other high-temperature industrial settings from melting down? The answer lies in a humble but remarkable material: High Alumina Bricks.

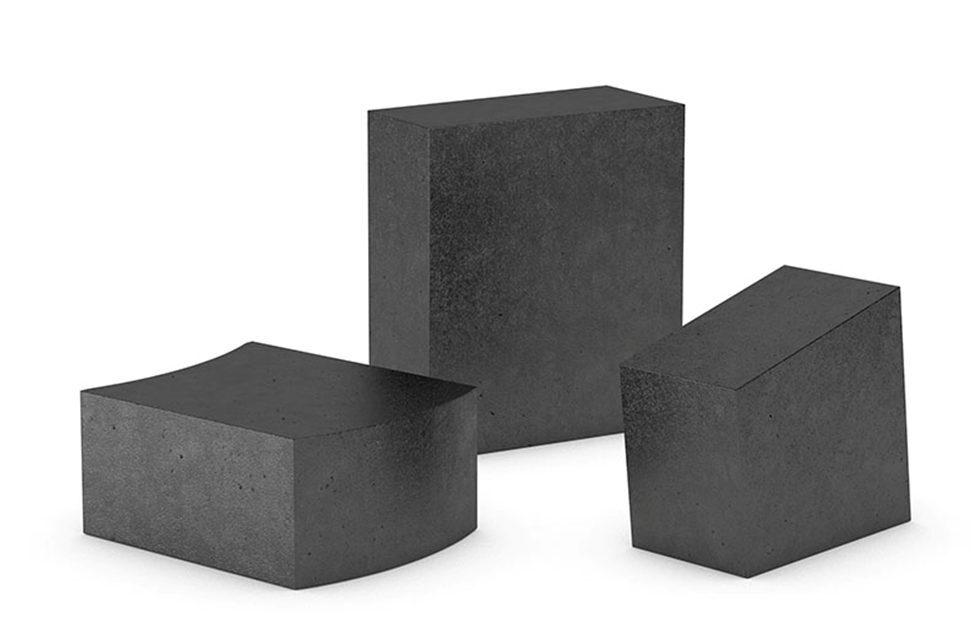

These aren’t your average construction bricks. Unlike the clay bricks used in building houses, high Alumina bricks are specifically designed to withstand scorching temperatures. Their secret ingredient? Alumina, also known as aluminum oxide (Al2O3).

What Makes High Alumina Bricks Different?

High Alumina Content: As the name suggests, these bricks boast a much higherAlumina content (typically over 55%) compared to regular fireclay bricks. Alumina is a highly heat-resistant compound, making the bricks ideal for withstanding extreme temperatures – often exceeding 1600°C (2912°F).

Superior Strength and Durability: The high Alumina content also translates to superior strength and durability. These bricks can resist wear and tear, chemical corrosion, and the harsh conditions found in industrial settings.

Excellent Thermal Properties: High Alumina bricks offer good thermal insulation, helping to maintain heat within the furnace or kiln while minimizing heat loss to the surrounding environment. This translates to improved efficiency and energy savings.

Where Are High Alumina Bricks Used?

These versatile bricks find application in various industries due to their exceptional high-temperature performance. Here are some common examples:

Cement Production: Lining the interiors of cement kilns, where temperatures can reach up to 1500°C (2732°F).

Steel Industry: Constructing furnace linings for steel melting and processing.

Glass Manufacturing: Forming the walls and roofs of glass furnaces, which operate at very high temperatures.

Power Generation: Lining boilers and incinerators to contain the intense heat generated during combustion.

Chemical Industry: Used in reactors and vessels involved in high-temperature chemical processes.

The Right Brick for the Job

High Alumina bricks come in various grades, with Alumina content ranging from 55% to over 90%. The appropriate grade selection depends on the specific application and the maximum temperatures encountered.

So, the next time you come across an industrial furnace or a towering kiln, remember – the unsung heroes keeping things hot (literally) might be high Alumina bricks. Their exceptional heat resistance and durability ensure smooth operations in some of the most demanding industrial environments.