The global shift towards renewable energy is accelerating as countries and industries strive to reduce carbon emissions, promote sustainability, and combat climate change. With growing investments in wind, solar, hydro, and other renewable energy sources, industries are evolving to meet the energy demands of the future. However, this transition requires advanced technologies and materials, especially in the high-temperature processes used in energy production.

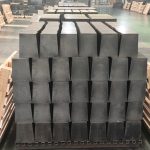

One key player in this shift is refractory materials. These high-performance materials are essential in supporting the demanding environments of renewable energy production, from the manufacturing of solar panels and wind turbines to bioenergy and geothermal power generation.

Why Refractory Solutions Are Vital for Renewable Energy

Refractory materials are designed to withstand extreme temperatures, mechanical stress, and chemical environments. In renewable energy production, they are used to line furnaces, kilns, reactors, and other equipment that operate at high temperatures. They contribute to the overall efficiency, durability, and sustainability of energy production processes.

Here are some specific ways in which refractory solutions are supporting the transition to renewable energy:

- Bioenergy Production

Bioenergy, which is derived from organic materials such as biomass, requires high-temperature processes such as combustion, gasification, and pyrolysis. Refractories are used to line the reactors and furnaces involved in these processes. They ensure the efficient conversion of organic materials into biofuels, while also enhancing the lifespan of the equipment. By providing optimal thermal insulation and protection, refractories help reduce energy loss and improve the overall efficiency of bioenergy plants. - Geothermal Power Generation

Geothermal energy production involves harnessing the heat from the Earth’s core to generate electricity. This process requires high-temperature equipment that can withstand extreme conditions. Refractory solutions are used in the construction of geothermal power plants to protect the equipment from corrosive gases and intense heat. With their ability to resist thermal shock and erosion, refractories ensure that geothermal plants operate at peak efficiency, helping to meet the growing demand for clean energy. - Solar Power and Concentrated Solar Thermal (CST) Systems

In concentrated solar thermal systems, mirrors focus sunlight onto a receiver, which is then used to heat a fluid and generate steam. The high temperatures involved in these systems require specialized refractories that can withstand thermal cycling, high radiation, and corrosion from the heated fluids. Refractory materials are used to line the receivers and storage tanks, enabling solar power plants to maintain efficient operations and store energy for later use. - Hydrogen Production

Hydrogen is increasingly being recognized as a clean fuel that can help decarbonize multiple sectors, including transportation and industry. Hydrogen production methods like steam methane reforming (SMR) and high-temperature electrolysis rely on equipment that operates at extreme temperatures. Refractories are essential in lining the reactors and furnaces used in these processes, helping maintain high levels of efficiency and protecting the equipment from heat damage.

Sustainability and the Future of Refractory Materials

As industries continue to shift towards renewable energy, sustainability will be at the forefront of innovation. Refractories are being designed to be more environmentally friendly, with a focus on reducing waste, extending product lifecycles, and incorporating recycled materials. This aligns with the growing emphasis on eco-friendly practices in renewable energy production.

At Pennekamp Middle East, we are committed to providing sustainable, high-performance refractory solutions that support the global shift to renewable energy. Our products are engineered to optimize efficiency, reduce environmental impact, and ensure the long-term success of renewable energy systems.

Why Choose Pennekamp Middle East for Your Refractory Solutions?

Pennekamp Middle East is a leading provider of advanced refractory solutions that are essential for renewable energy production. Our team works closely with clients to develop tailored solutions that meet the unique demands of renewable energy projects. Here’s why we’re the preferred partner for refractory materials:

- Customization: We offer tailored refractory products designed to meet the specific needs of renewable energy applications.

- Sustainability: Our refractories are designed to promote sustainability, both in terms of performance and environmental impact.

- Expertise: With years of experience in the refractory industry, we provide expert support to help clients optimize their operations and achieve energy efficiency.

Conclusion

The transition to renewable energy presents both challenges and opportunities. Refractory materials are integral to this process, ensuring the efficiency, durability, and sustainability of high-temperature systems used in renewable energy production. At Pennekamp Middle East, we are proud to provide cutting-edge refractory solutions that support the global shift to cleaner, greener energy.

Contact Pennekamp Middle East today to learn more about how our refractory solutions can help power the future of renewable energy.