In industries that operate under extreme temperatures, refractories are essential for protecting equipment and ensuring the safe and efficient performance of processes. However, one of the challenges faced by refractories is the impact of thermal expansion. As refractories are exposed to high temperatures, they expand and contract, which can affect their integrity, performance, and lifespan. Understanding the role of thermal expansion in refractories is crucial for optimizing material selection, improving operational efficiency, and reducing downtime.

What is Thermal Expansion?

Thermal expansion refers to the change in volume or size of a material as it heats up or cools down. For refractories, this can result in a slight expansion when exposed to high temperatures, followed by contraction when the material cools. While this behavior is normal, it can lead to stress, cracking, and damage if not properly managed.

How Thermal Expansion Affects Refractory Performance

- Cracking and Deformation: When refractories expand unevenly or too rapidly, it can lead to internal stresses that cause cracking. Cracks in refractory linings compromise their protective function and may expose underlying materials to damage, ultimately leading to equipment failure and increased maintenance costs.

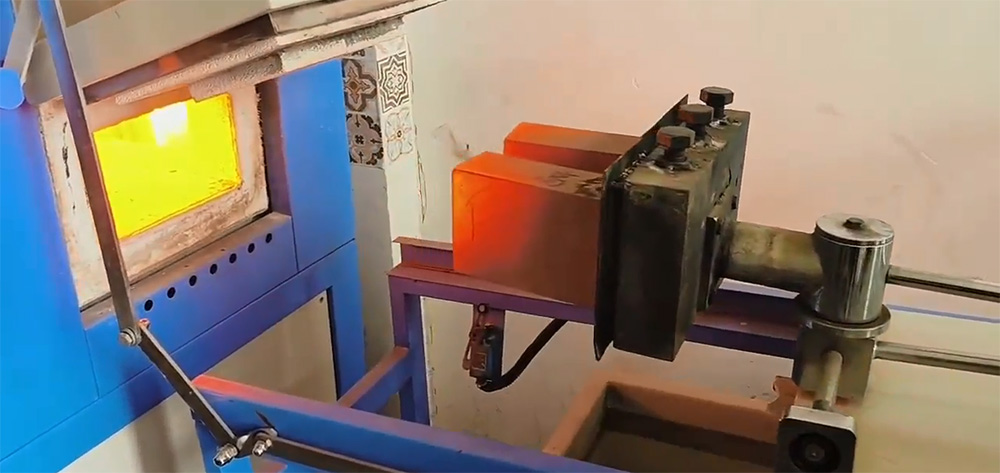

- Thermal Shock Resistance: Thermal expansion plays a significant role in a material’s ability to resist thermal shock, which occurs when there is a sudden temperature change. Refractories that are not designed to accommodate thermal expansion may experience cracking or spalling when exposed to rapid temperature shifts, such as when a furnace is started or shut down.

- Reduced Lifespan: Continuous exposure to fluctuating temperatures causes refractories to expand and contract repeatedly. Over time, this cyclic expansion and contraction can weaken the material and reduce its lifespan. Frequent replacements or repairs are necessary when refractories fail due to thermal expansion, leading to increased downtime and higher maintenance costs.

- Slag and Metal Penetration: In furnaces and kilns, thermal expansion can affect the integrity of refractory linings. Once damaged by thermal stresses, refractory materials become more susceptible to slag or molten metal penetration. This compromises the furnace’s efficiency and increases the risk of contaminating the steel or other metals being produced.

Managing Thermal Expansion in Refractories

- Material Selection: The key to mitigating the effects of thermal expansion is choosing refractories with the right thermal expansion properties for the specific application. Some refractories are formulated with materials that exhibit low thermal expansion, making them more resistant to cracking and deformation under temperature fluctuations.

- Pre-Firing and Proper Installation: Refractories can undergo pre-firing or controlled heating during installation to minimize the effects of thermal expansion. This helps relieve internal stresses that could lead to cracks and ensures that the material is stable before being exposed to operating temperatures.

- Thermal Expansion Coefficient Control: Manufacturers can control the coefficient of thermal expansion in refractories by using specific additives and compounds. By fine-tuning the thermal expansion characteristics, refractories are better suited to handle temperature changes without compromising performance.

- Regular Maintenance and Inspection: Continuous monitoring and maintenance of refractory linings can help detect early signs of thermal expansion issues. Regular inspections allow for timely repairs or replacements, preventing further damage and extending the overall lifespan of refractory materials.

Pennekamp Middle East’s Refractory Solutions for Thermal Expansion

At Pennekamp Middle East, we specialize in providing high-quality refractories designed to withstand the challenges posed by thermal expansion. Our refractories are engineered for durability, thermal shock resistance, and long-lasting performance, ensuring that your industrial processes run smoothly and efficiently.

By choosing Pennekamp Middle East, you benefit from:

- Tailored Solutions: Our refractories are customized to meet the specific thermal requirements of your operation, ensuring optimal performance and protection.

- Enhanced Durability: Our materials are formulated to minimize the impact of thermal expansion, extending the lifespan of your equipment and reducing the need for frequent maintenance.

- Reduced Operational Costs: By preventing damage due to thermal stresses, our refractories help minimize downtime, maintenance costs, and replacement expenses.

Conclusion

Thermal expansion is a critical factor that impacts the performance and longevity of refractories in high-temperature environments. Understanding its effects and selecting the right materials for each application is essential for optimizing performance, reducing maintenance, and extending the lifespan of industrial equipment.

At Pennekamp Middle East, we provide refractory solutions designed to mitigate the effects of thermal expansion, ensuring that your operations remain safe, efficient, and cost-effective.

Contact Pennekamp Middle East today to learn more about our high-performance refractories and how they can improve the efficiency and durability of your high-temperature operations.