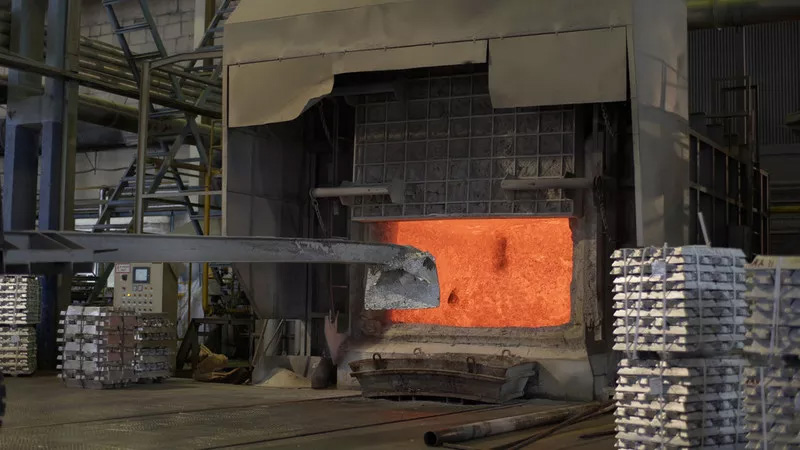

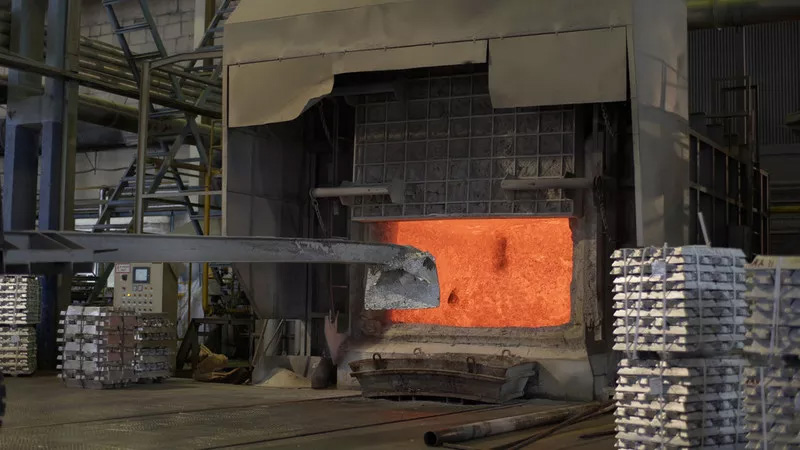

In the competitive world of foundries, performance optimization is crucial to ensure high-quality castings, minimize costs, and maintain operational efficiency. Custom refractory solutions are a key factor in achieving these objectives. By tailoring refractories to meet the unique needs of each foundry, businesses can significantly enhance productivity, reduce downtime, and improve the longevity of equipment and molds.

What are Custom Refractory Solutions?

Custom refractory solutions refer to refractory materials specifically designed to meet the unique demands of a foundry’s operations. These solutions take into account factors such as temperature range, chemical exposure, and mechanical stresses that are specific to the foundry’s processes. By customizing the refractory material, foundries can optimize their casting operations, increase throughput, and reduce wear and tear on their equipment.

Key Benefits of Custom Refractory Solutions for Foundries

- Optimized Performance: Custom refractories are designed to suit the specific thermal, chemical, and mechanical requirements of the foundry process. This ensures that the refractories provide optimal performance in extreme conditions, enhancing the overall efficiency and effectiveness of the operation.

- Enhanced Durability: Foundry operations expose refractories to high temperatures and aggressive chemicals. Custom refractory materials are engineered to withstand these harsh conditions, improving the durability of molds, liners, and furnaces. This results in longer service life, reduced maintenance, and fewer replacements.

- Reduced Downtime: Downtime can be costly in foundries, particularly when equipment fails unexpectedly. Custom refractory solutions reduce the likelihood of premature failure by offering better protection against thermal shock, corrosion, and wear. As a result, foundries experience fewer disruptions and increased productivity.

- Improved Casting Quality: With the right refractory materials, foundries can achieve better temperature control during the casting process. Custom solutions ensure uniform cooling rates, reduced defects like cracks or porosity, and better mold integrity, leading to higher-quality castings and fewer reworks.

- Cost Efficiency: While custom refractories may have a higher initial cost, they ultimately provide better performance, durability, and longevity. This translates to fewer repairs and replacements, lower energy consumption, and more efficient operations, making them a cost-effective choice in the long run.

Pennekamp Middle East’s Custom Refractory Solutions for Foundries

At Pennekamp Middle East, we understand that each foundry has its unique challenges and requirements. That’s why we offer a range of custom refractory solutions designed to optimize your foundry’s performance. Our team works closely with you to develop tailored materials that meet your specific needs and ensure your operations run smoothly and efficiently.

Benefits of Choosing Pennekamp Middle East for Your Custom Refractory Needs:

- Tailored Designs: We customize our refractories to address the specific demands of your foundry, from temperature extremes to chemical resistance.

- Long-Lasting Durability: Our products are designed to withstand high temperatures, reducing wear and tear and extending equipment life.

- Improved Efficiency: Our custom refractories enhance operational performance, leading to increased throughput, fewer defects, and lower energy consumption.

- Reduced Maintenance Costs: With superior durability and performance, our refractories reduce the need for frequent repairs and replacements.

Conclusion

Custom refractory solutions are crucial for improving the performance and efficiency of foundries. By selecting the right materials tailored to your unique processes, you can enhance productivity, improve casting quality, and reduce operational costs.

At Pennekamp Middle East, we specialize in providing high-quality, custom refractory materials that are designed to meet the specific needs of your foundry. Our solutions help optimize your processes, increase durability, and deliver long-term success.

Contact Pennekamp Middle East today to learn more about our custom refractory solutions and how they can improve the performance of your foundry.