In the high-speed, high-intensity environment of a Basic Oxygen Furnace, the final step of tapping the steel is a moment of critical importance. The success of this step hinges entirely on the performance of a single, highly engineered component: the tap hole. Far from being a simple opening, the BOF tap hole is a sophisticated refractory channel designed to perform a crucial dual function that directly impacts the quality of the final product.

Its primary role is to provide a controlled, consistent, and predictable stream of molten steel as it pours from the furnace into the ladle. Simultaneously, it must act as a dam, effectively holding back the thick layer of corrosive molten slag that floats on top of the steel. Preventing this slag from entering the ladle—a process known as slag-free tapping—is essential for meeting modern steel cleanliness standards.

An Environment of Extremes

The tap hole operates in arguably the most punishing environment within the furnace. It must withstand a relentless, multi-faceted assault:

- Extreme Thermal Shock: It endures the instantaneous heat of molten steel, well over 1600°C.

- High-Velocity Abrasion: The force of up to 300 tons of steel flowing through a narrow channel creates immense erosive force.

- Aggressive Chemical Attack: The refractory is in direct contact with both the liquid steel and the highly corrosive furnace slag.

Designing for Durability: The MgO-C Solution

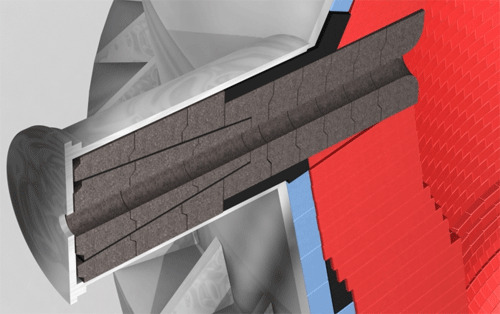

To survive these conditions, BOF tap holes are constructed from some of the most advanced refractory materials available. The solution typically involves high-performance, pre-formed tap hole sleeves or pipes made from resin-bonded Magnesia-Carbon (MgO-C).

This material is the industry standard for this application for several key reasons:

- High Refractoriness: Magnesia provides an extremely high melting point.

- Excellent Slag Resistance: The MgO is chemically resistant to the basic BOF slag.

- Superior Thermal Shock Resistance: The presence of carbon in the mix improves the material’s elasticity and ability to withstand rapid temperature changes without cracking.

- Low Wettability: Carbon makes the refractory less “wettable” by molten slag and steel, which helps prevent clogging and reduces corrosion.

The performance and lifespan of the BOF tap hole are critical operational metrics. Its reliability dictates the smoothness of the tapping process, the quality of the steel produced, and the overall safety and productivity of the furnace.

Ensure Reliable Tapping with High-Performance Refractories

At Pennekamp Middle East, we provide a comprehensive range of refractory solutions for the BOF, including premium-quality MgO-C tap hole sleeves and pipes. Our products are engineered for maximum durability and reliable performance in the most demanding steelmaking environments.

Contact us today to learn how our BOF tap hole solutions can improve your tapping performance and steel quality.