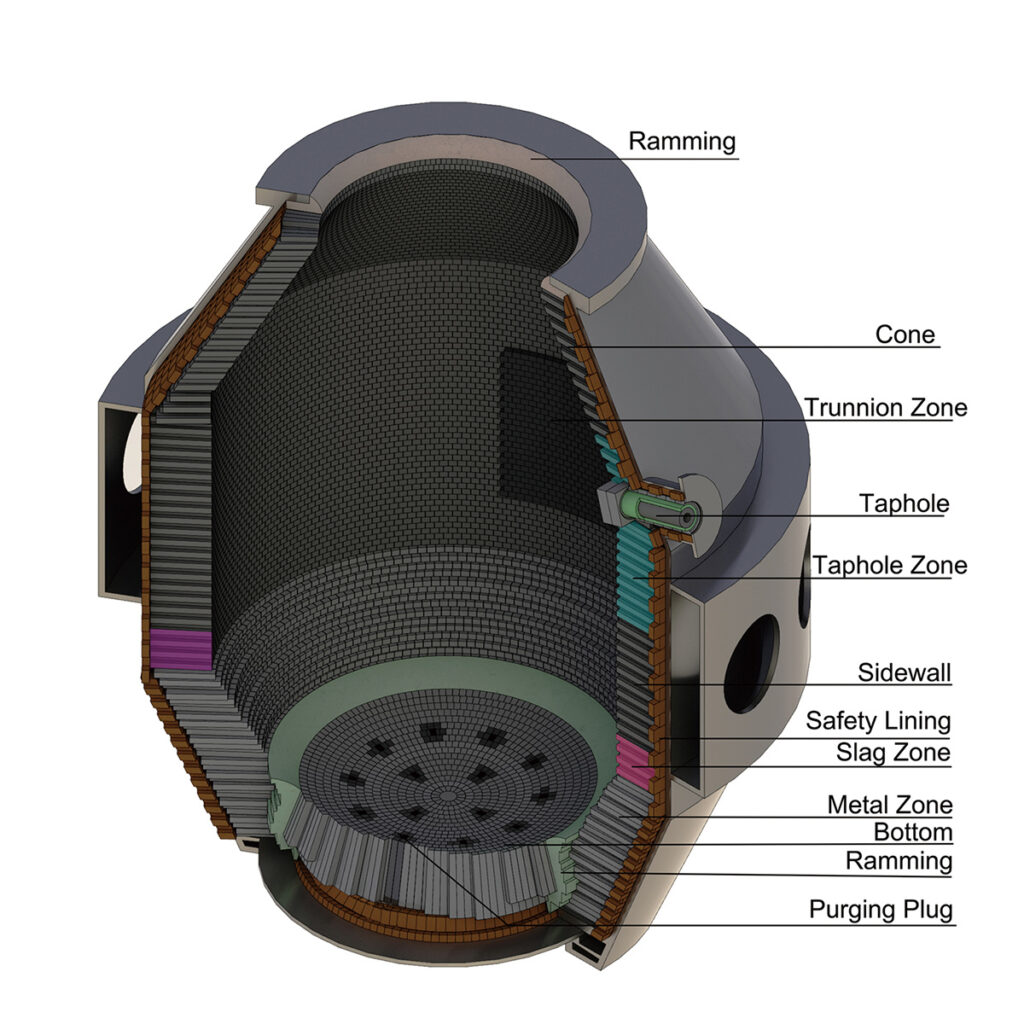

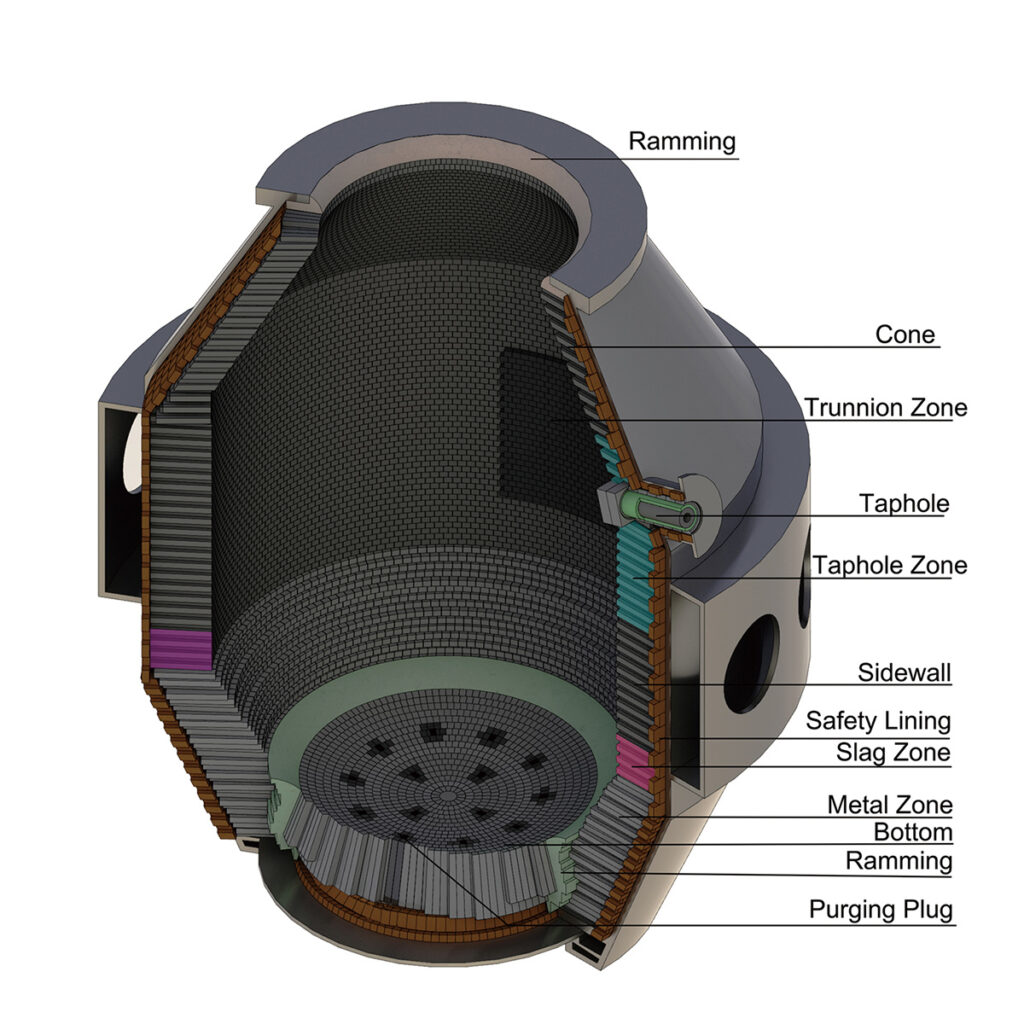

The Basic Oxygen Furnace (BOF) is the heart of modern steelmaking, where molten iron is transformed into steel. Within this furnace, the tap hole plays a critical role, acting as the crucial passage for the outflow of molten steel during the tapping process.

High Heat, High Pressure: The Demanding Environment of the Tap Hole

The BOF tap hole endures extreme conditions. It faces temperatures exceeding 1600°C (2912°F) and experiences immense pressure from the molten steel. Additionally, the tap hole is constantly exposed to the erosive effects of slag and the scouring action of the tapping stream.

Refractory Solutions for a Durable Tap Hole

To withstand these harsh conditions, the tap hole relies on high-performance refractory materials. These materials are specially formulated to offer exceptional thermal resistance, slag corrosion resistance, and mechanical strength.

At Pennekamp Middle East, we are a leading provider of premium tap hole refractories for BOF applications. Our product range includes:

- Tap Hole Blocks: Designed to form the core of the tap hole, offering exceptional durability and minimal erosion.

- Pre-Tap Plugs: Temporary plugs used to control the initial slag flow during tapping.

- Tapping Nozzles: Channel the molten steel flow during tapping, ensuring a smooth and controlled process.

Benefits of High-Quality Tap Hole Refractories

Utilizing high-quality tap hole refractories offers several advantages for steel producers:

- Extended Tap Hole Life: Durable refractories minimize erosion and wear, leading to longer tap hole life and reduced refractory replacement costs.

- Improved Tapping Efficiency: Optimized tap hole design and smooth refractory surfaces ensure efficient and controlled tapping processes.

- Reduced Downtime: Extended tap hole life minimizes refractory maintenance needs and reduces downtime for steel production.

- Enhanced Steel Quality: Proper tap hole design and efficient tapping contribute to cleaner steel by minimizing slag inclusion.

Optimizing BOF Tap Hole Performance

Beyond selecting the right refractories, several practices can further optimize BOF tap hole performance:

- Proper Installation: Meticulous installation techniques ensure optimal performance and lifespan of the refractory materials.

- Temperature Control: Maintaining consistent and controlled temperatures within the BOF minimizes refractory stress and extends tap hole life.

- Regular Maintenance: Scheduled inspections and preventive maintenance practices help identify and address potential issues before they escalate.

Pennekamp Middle East: Your Partner for BOF Tap Hole Solutions

Pennekamp Middle East is your trusted partner for all your BOF tap hole needs. We offer a comprehensive range of high-quality refractory materials, expert technical support, and a commitment to finding the optimal solutions for your specific BOF operations.

Contact Pennekamp Middle East today! We can help you select the ideal tap hole refractories and optimize your BOF tapping process for increased efficiency, cost savings, and improved steel quality.