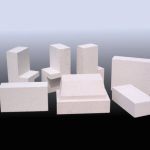

When it comes to thermal insulation, choosing the right materials is crucial for optimizing energy efficiency and maintaining optimal operating conditions. Among the various options available, refractory ceramic fibers (RCFs) have gained significant recognition for their outstanding properties and versatile applications. RCFs are lightweight, high-performance insulation materials capable of withstanding extreme temperatures. They are composed of inorganic materials such as alumina and silica, ensuring excellent thermal stability and insulation capabilities.

Energy Efficiency:

One of the primary advantages of using refractory ceramic fibers in thermal insulation is the significant improvement in energy efficiency. RCFs possess excellent thermal conductivity properties, which allow them to effectively reduce heat transfer. By minimizing heat loss or gain, RCFs enable better temperature control, reducing the energy required for heating or cooling processes.

High-Temperature Applications:

RCFs exhibit exceptional resistance to high temperatures, making them ideal for applications that involve extreme heat conditions. With a high melting point and low thermal expansion, RCFs can withstand temperatures exceeding 2300°C (4172°F). This property enables them to provide reliable thermal insulation in industries such as steel, cement, glass, and petrochemicals, where elevated temperatures are prevalent.

Flexibility and Ease of Installation:

Another significant advantage of refractory ceramic fibers is their flexibility and ease of installation. RCFs can be shaped and formed into various configurations to suit the specific requirements of different applications. Whether it is lining a curved surface or insulating complex equipment, RCFs can be easily molded to achieve a precise fit, minimizing gaps and ensuring optimal thermal insulation.

Safety and Environmental Considerations:

In addition to their exceptional thermal insulation properties, refractory ceramic fibers offer several safety and environmental advantages. RCFs are non-combustible and do not contribute to the spread of fire, enhancing the overall fire safety of insulated structures or equipment. Their low thermal conductivity also minimizes the risk of thermal bridges, preventing potential heat-related accidents.

RCFs are also known for their durability, requiring minimal maintenance and replacement over time. This not only reduces the overall cost of ownership but also minimizes waste generation, contributing to a more sustainable and environmentally friendly approach to thermal insulation.

Conclusion:

Refractory ceramic fibers (RCFs) offer a multitude of advantages when it comes to thermal insulation. Their exceptional thermal conductivity properties enhance energy efficiency and reduce operational costs by minimizing heat transfer. With their ability to withstand high temperatures and resist thermal shock, RCFs are suitable for demanding industrial applications where extreme heat is a factor.

Looking to enhance thermal insulation and improve energy efficiency in your industry? Contact Pennekamp Middle East today to explore our range of refractory ceramic fiber products. Our team of experts will guide you in choosing the right materials and solutions tailored to your specific needs. Don’t miss out on the advantages of using refractory ceramic fibers for optimal thermal insulation. Take the first step towards efficiency and sustainability by contacting us now.