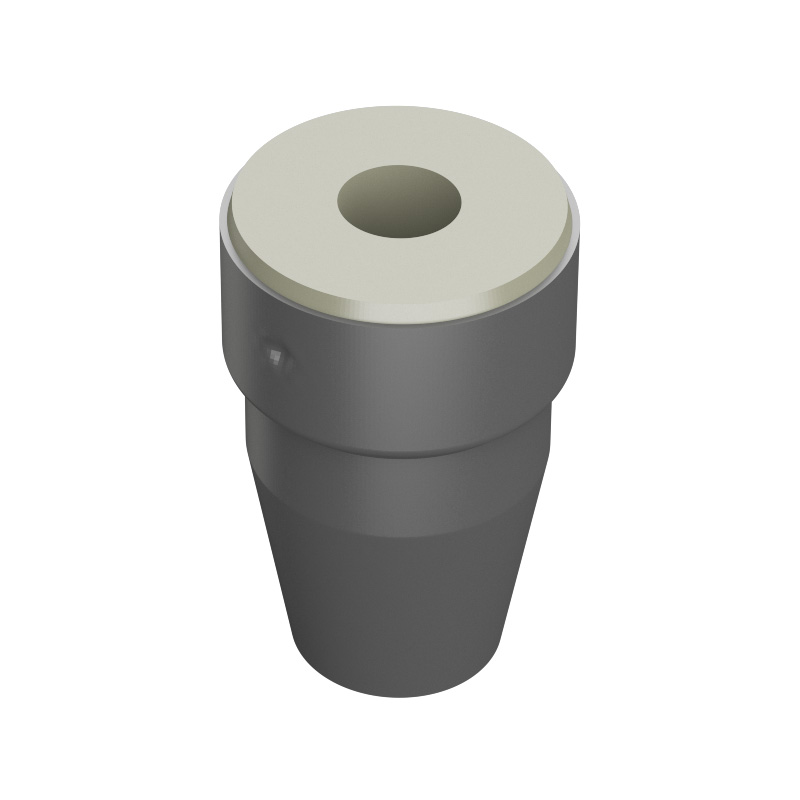

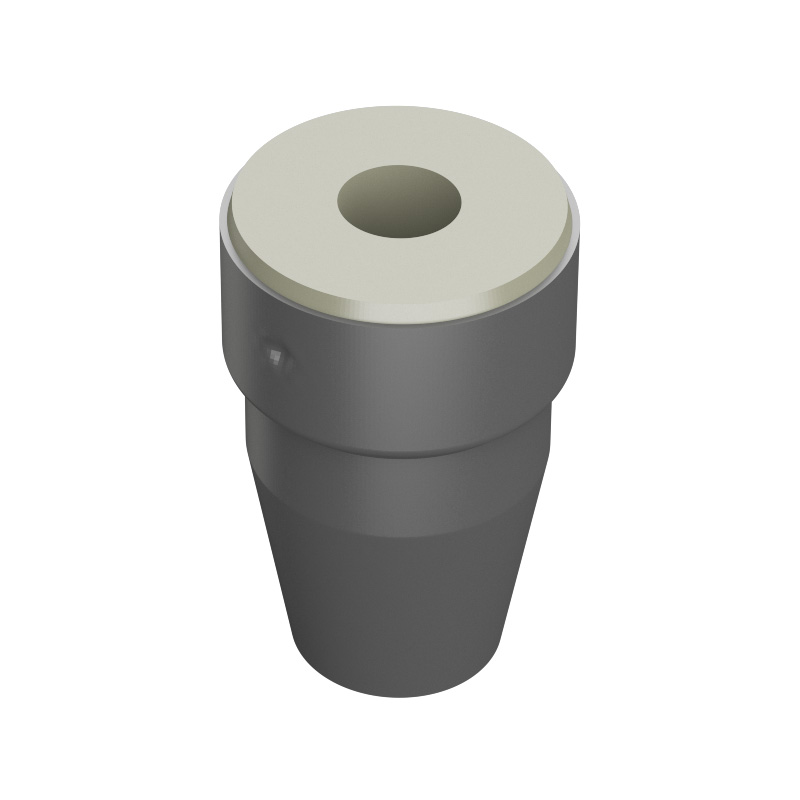

Ladle furnaces play a vital role in the steelmaking process, where molten steel is refined and temperature-controlled. The collector nozzles in ladle furnaces are essential components that facilitate the transfer of molten steel to other parts of the production line while maintaining precise control over temperature and chemical composition. Due to the extreme conditions in which these nozzles operate, choosing the right refractory materials is critical for ensuring performance, durability, and safety.

In this blog, we’ll explore the importance of refractories used in ladle furnace collector nozzles and how these materials contribute to the overall efficiency of steelmaking.

The Role of Ladle Furnace Collector Nozzles

Ladle furnace collector nozzles are responsible for directing molten steel from the ladle furnace into various parts of the steel production process, such as the casting process. These nozzles experience high temperatures, thermal shock, mechanical stress, and exposure to aggressive chemicals, making them vulnerable to wear and tear. Therefore, using high-quality refractories that can withstand these extreme conditions is essential for maintaining smooth, efficient operations.

Challenges Faced by Collector Nozzles

- Extreme High-Temperature Exposure: Collector nozzles are exposed to molten metal temperatures that can exceed 1,500°C, demanding refractories with excellent heat resistance to prevent degradation.

- Thermal Shock and Cycling: The rapid heating and cooling cycles during ladle furnace operations subject the nozzles to thermal shock, which can cause cracking and failure if the refractories are not thermally stable.

- Chemical Erosion: The nozzles are also exposed to molten slag, steel, and gases that can cause significant chemical corrosion. Choosing refractories with excellent chemical resistance is vital to protecting the nozzle structure.

- Mechanical Stress: The weight of the molten steel and the physical demands of the ladle furnace can subject the nozzles to significant mechanical stress. Refractory materials must have sufficient mechanical strength to endure these stresses without failure.

How Refractory Materials Meet These Challenges

- High-Temperature Resistance: Refractory materials such as Magnesia Carbon and Alumina provide superior heat resistance, maintaining the integrity of the ladle furnace collector nozzles even under the intense heat of molten steel.

- Thermal Shock Resistance: Magnesite and Spinel-based refractories offer outstanding resistance to thermal shock, making them ideal for the rapidly fluctuating temperatures that occur during ladle furnace operations.

- Chemical Resistance: High-quality refractories used in collector nozzles are engineered to resist corrosion caused by molten slag, steel, and other aggressive chemicals. Magnesia-based and Chromium Oxide-based materials provide excellent protection against chemical erosion.

- Mechanical Strength: Refractories like Sintered Mullite and Fused Alumina offer excellent mechanical strength, allowing them to withstand the heavy load and mechanical stresses in the ladle furnace environment.

Pennekamp Middle East’s Refractory Solutions for Ladle Furnace Collector Nozzles

At Pennekamp Middle East, we provide specialized refractory solutions designed to enhance the performance and durability of ladle furnace collector nozzles. Our high-performance refractories are tailored to meet the rigorous demands of the steelmaking industry, offering superior heat resistance, thermal shock protection, and chemical stability.

Why Choose Pennekamp Middle East?

- Tailored Refractory Solutions: We provide customized refractory materials that are specifically engineered for ladle furnace collector nozzles, ensuring optimal performance in high-temperature conditions.

- Long-Term Durability: Our products are designed for longevity, reducing the need for frequent replacements and minimizing downtime in the steelmaking process.

- Expertise in Steelmaking: With extensive experience in the steel industry, we understand the unique challenges faced by ladle furnaces and offer reliable, high-quality solutions to meet those needs.

Conclusion

Refractories for ladle furnace collector nozzles play a crucial role in ensuring the efficiency, safety, and longevity of steelmaking operations. By offering superior heat resistance, thermal shock stability, and chemical protection, the right refractories can help minimize downtime, reduce maintenance costs, and improve the overall performance of the steel production process.

At Pennekamp Middle East, we provide industry-leading refractory products designed to withstand the extreme conditions of ladle furnace collector nozzles, helping your operations achieve optimal efficiency and safety.

Contact Pennekamp Middle East today to learn more about our refractory solutions for ladle furnace collector nozzles and how we can help enhance the performance of your steelmaking operations.