Refractories for BOF Slag Ball: A Key to Optimized Steelmaking

In the steelmaking industry, Basic Oxygen Furnaces (BOF) play a pivotal role, producing high-quality steel with precision and efficiency. However, one of the biggest challenges in BOF operations is managing slag. Slag balls, which are formed during the steel refining process, require robust and reliable refractory solutions to ensure the furnace operates at peak performance.

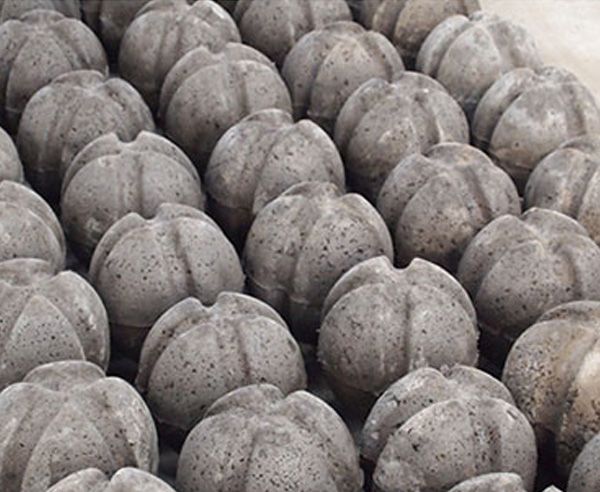

What Are BOF Slag Balls?

Slag balls are accumulations of slag, a byproduct of the steelmaking process, that solidify into spherical shapes. These balls are created during the refining phase, where impurities from molten steel are removed. The slag not only protects the molten steel but also maintains the thermal stability of the BOF.

Given their exposure to extreme temperatures and abrasive conditions, the refractories used to manage slag balls must be capable of withstanding harsh environments while maintaining their integrity.

Why High-Quality Refractories Matter for BOF Slag Balls

Effective refractories are critical for ensuring the longevity and efficiency of BOF operations. Here’s why:

- Thermal Resistance: BOF slag balls are exposed to temperatures exceeding 1,600°C. High-quality refractories are essential to withstand such extreme conditions without degradation.

- Abrasion Resistance: The constant movement and interaction between molten steel and slag balls can cause wear and tear. Durable refractories ensure minimal erosion and maximum productivity.

- Energy Efficiency: Properly designed refractory solutions reduce energy loss, allowing for optimized heat retention and improved operational efficiency.

- Cost-Effectiveness: Longer-lasting refractories reduce downtime and maintenance costs, translating into significant savings for steelmakers.

Pennekamp Middle East: Your Partner in BOF Refractory Solutions

At Pennekamp Middle East, we specialize in delivering state-of-the-art refractory raw materials and finished products tailored to the needs of steelmakers. Our solutions for BOF slag balls are engineered to:

- Minimize wear and maximize durability under extreme conditions.

- Enhance thermal efficiency, ensuring optimal furnace performance.

- Provide customizable options to meet unique operational requirements.

Innovating for Tomorrow

As the steel industry evolves, so do the challenges it faces. At Pennekamp Middle East, we are committed to staying ahead of these challenges with cutting-edge refractory solutions that combine durability, efficiency, and sustainability. By choosing our products, you’re investing in reliability and performance that your BOF operations can count on.

Conclusion

Refractories for BOF slag balls are more than just materials—they’re essential components for efficient and reliable steel production. With Pennekamp Middle East’s expertise, you can ensure your operations achieve maximum performance while reducing costs and downtime.

Ready to optimize your BOF operations? Contact us today to learn more about our innovative refractory solutions.