The steel production process is an intricate dance of intense heat, molten metal, and specialized equipment. While the colossal blast furnaces and towering casting bays often steal the spotlight, a less conspicuous but equally crucial player sits quietly behind the scenes: the ladle furnace. This workhorse vessel plays a vital role in ensuring the quality and consistency of molten steel, and its efficient operation relies heavily on a specific type of refractory material – ramming masses.

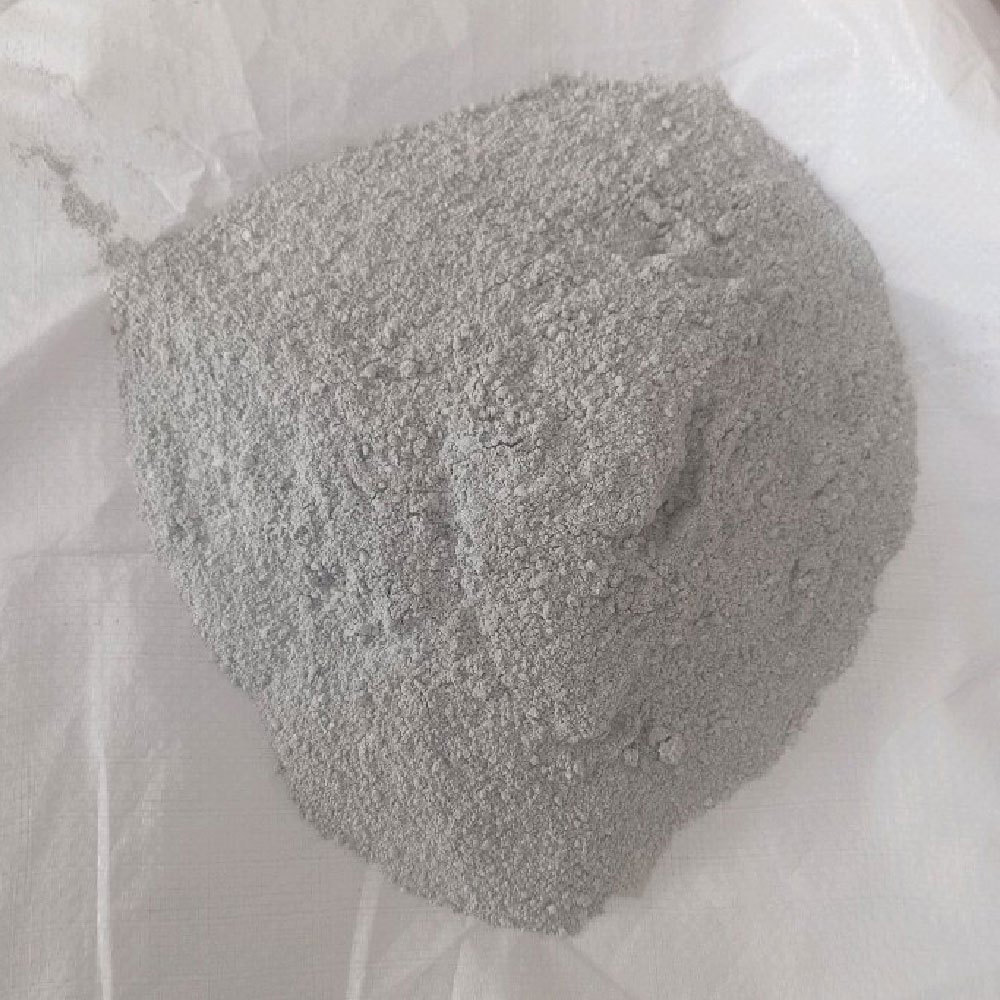

What are Ramming Masses for Ladle Furnace?

Ramming masses are precisely formulated dry refractory materials designed to be compacted and shaped into desired configurations upon installation. They are a versatile solution for various applications within the ladle furnace, offering several advantages over pre-fired refractory shapes:

- Cost-Effective: Ramming masses generally require less initial investment compared to pre-fired shapes.

- Enhanced Flexibility: They can be readily molded to fit complex geometries within the ladle furnace, minimizing the need for intricate pre-fired shapes.

- Efficient Installation: Ramming masses can be applied quickly and efficiently, minimizing downtime during furnace repairs or relining.

- Good Self-Bonding Properties: These materials exhibit good self-bonding characteristics, forming a cohesive and robust lining after installation.

Composition of Ramming Masses for Ladle Furnace:

The specific composition of a ramming mass for ladle furnace applications varies depending on the intended purpose and operational requirements. However, some common components include:

- Refractory Aggregates: These form the backbone of the ramming mass, typically consisting of high-purity materials like alumina, magnesia, and chromite. The choice of aggregate influences the thermal resistance, chemical stability, and mechanical strength of the final product.

- Binders: Binders play a crucial role in holding the refractory aggregates together during installation and ensuring the ramming mass remains cohesive after setting. Common binders include chemical binders like phosphates and sulfites, or hydraulic binders like calcium aluminate cement.

- Additives: Various additives can be incorporated into the ramming mass to enhance specific properties. For instance, antioxidants may be added to improve slag resistance, while wetting agents can facilitate easier compaction during installation.

Key Properties of Ramming Masses for Ladle Furnace:

To effectively perform in the demanding ladle furnace environment, ramming masses must possess several key properties:

- High Thermal Resistance: The ladle furnace subjects the refractory lining to high temperatures, typically exceeding 1500°C. Therefore, the ramming mass must possess exceptional thermal resistance to maintain structural integrity and minimize heat loss.

- Good Chemical Stability: Molten steel and slags within the ladle furnace can be chemically aggressive. The ramming mass must exhibit good resistance to chemical attack to prevent premature degradation and ensure the longevity of the furnace lining.

- Adequate Mechanical Strength: The ladle furnace lining experiences various mechanical stresses during operation, such as those induced by molten steel movement and ladle tilting. The ramming mass requires sufficient mechanical strength to withstand these stresses and prevent cracking or spalling.

- Good Workability: For efficient installation, the ramming mass should offer good workability. This ensures it can be readily compacted and shaped to fit the desired geometry within the ladle furnace.

- Good Densification: After installation, the ramming mass needs to achieve adequate densification to form a strong and impermeable lining.

Applications of Ramming Masses for Ladle Furnace:

Ramming masses serve a variety of purposes within the ladle furnace, each requiring a formulation optimized for specific performance demands:

- Working Lining: The working lining forms the primary refractory barrier within the ladle furnace, directly exposed to molten steel and high temperatures. Ramming masses for this application typically have a high alumina content for excellent thermal resistance and chemical stability.

- Slag Zone: The slag zone in the ladle furnace separates the molten steel from the overlying slag layer. Ramming masses designed for this area often possess a higher magnesia content to enhance resistance to slag attack.

- Induction Coils: Induction furnaces utilize electromagnetic fields for heating the molten steel. Ramming masses for this area require good electrical insulation properties to minimize energy losses.

- Ladle Bottom: The ladle bottom experiences significant wear and tear due to factors like slag accumulation and high temperatures. Ramming masses formulated for this application typically offer superior mechanical strength and erosion resistance.

Pennekamp Middle East: Your Partner for High-Performance Ramming Masses for Ladle Furnace

Pennekamp Middle East is a leading provider of high-quality ramming masses specifically designed for ladle furnace applications. We understand the diverse requirements of different ladle furnace zones and offer a comprehensive range of formulations to meet your specific needs. Our team of refractory experts can assist you in selecting the optimal ramming mass