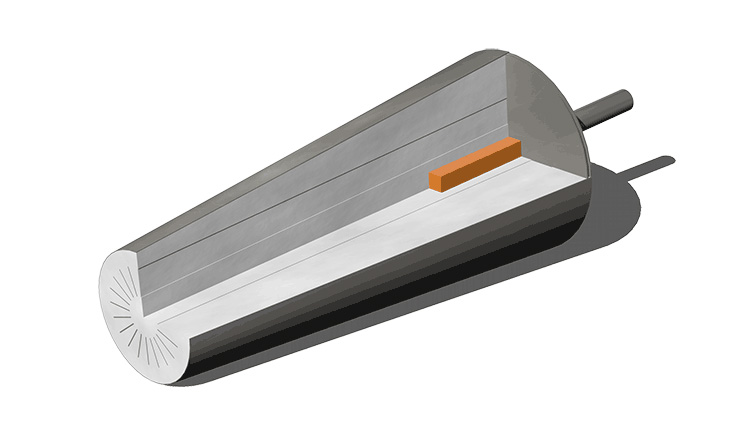

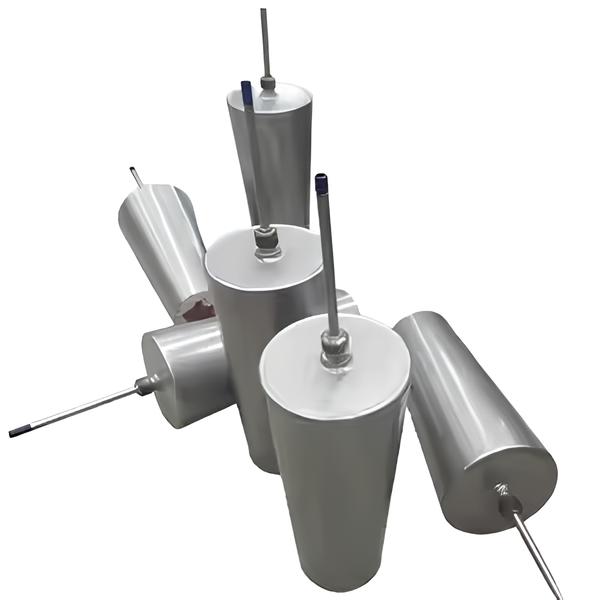

Purging Plug for Converter: A Crucial Component in Steelmaking

- Home

- Pennekamp Middle East

- Purging Plug for Converter: A Crucial Component in Steelmaking

At PENNEKAMP Middle East LLC, we are a leading provider of high-quality refractory products for businesses across a wide range of Refractory and Steel industries. With over 25 years of experience in the refractory industry, we have established ourselves as a reliable partner for companies looking for durable and cost-effective refractory solutions.

Raw Materials PDF

Finished Products PDF

Raw Materials PDF

Finished Products PDF