Mould Fluxes

LIQUID POWDER

How it works:

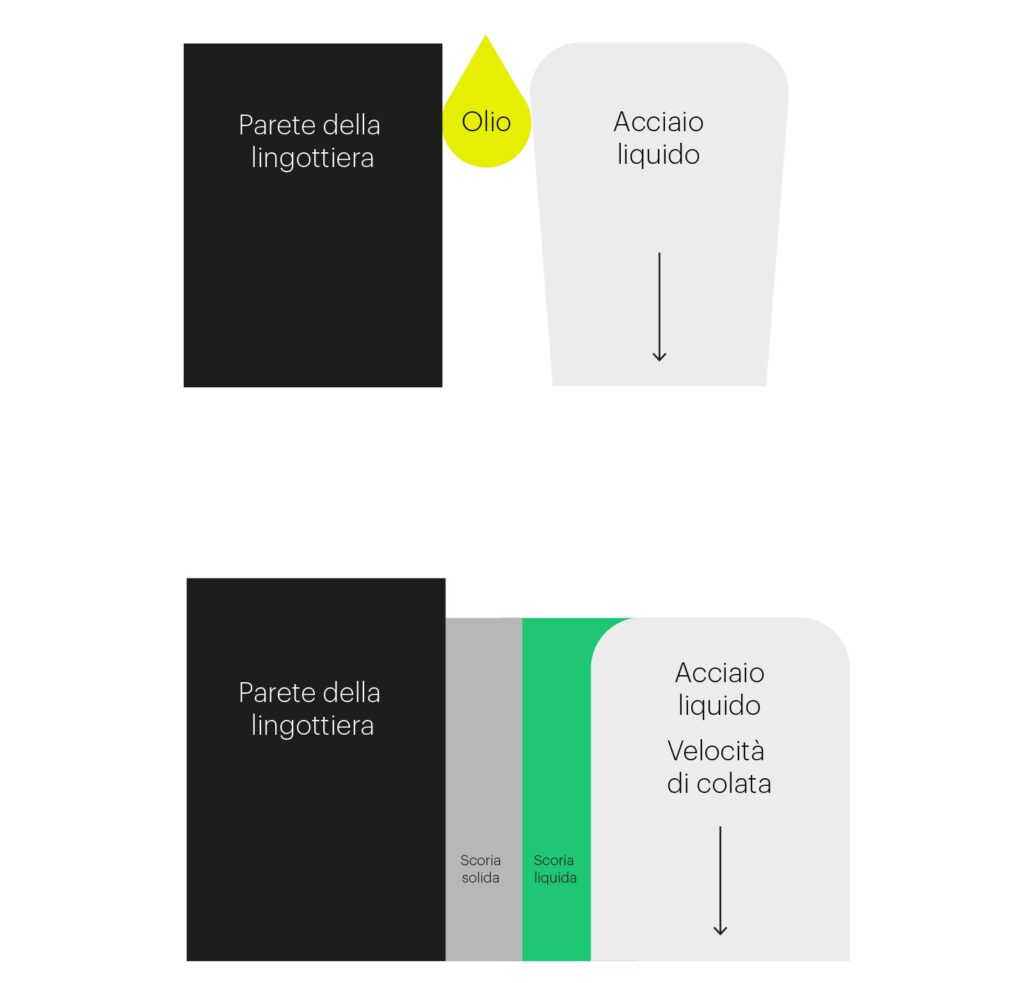

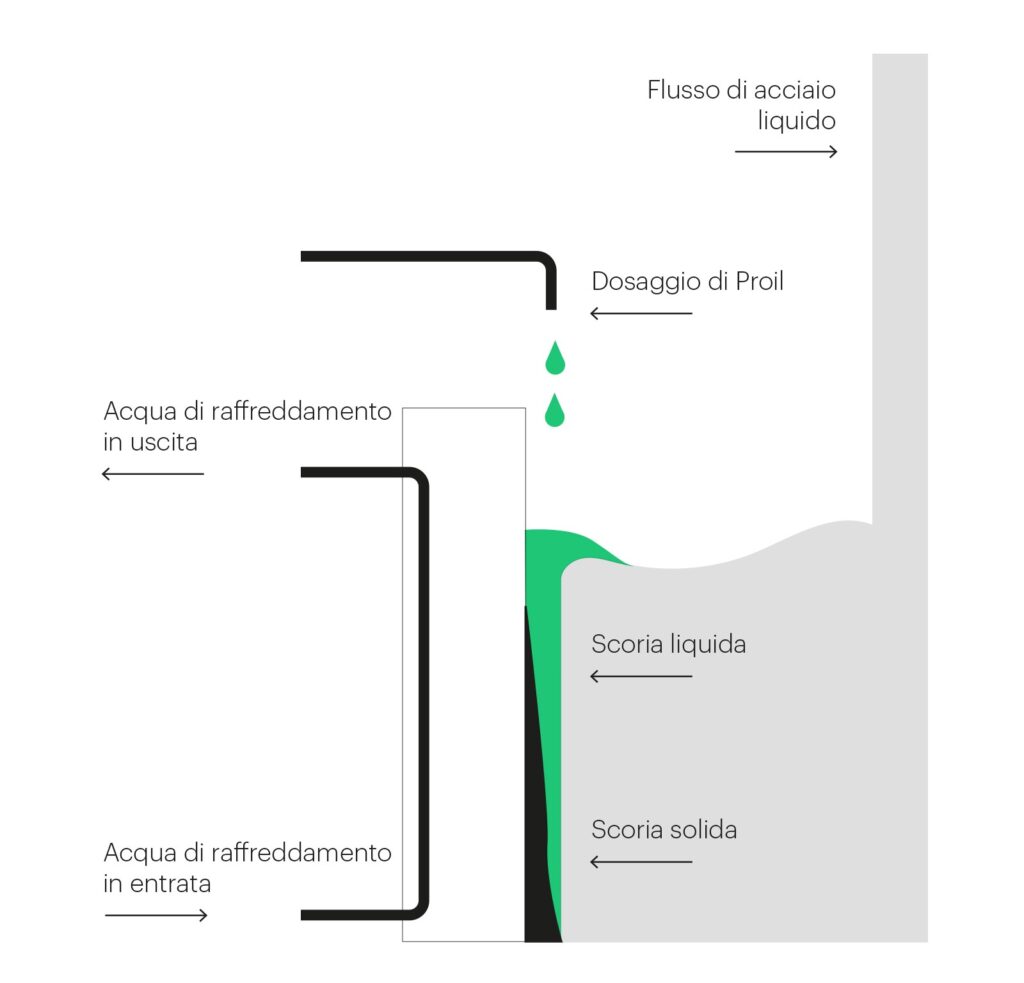

The product, poured from above into the mould, acts by forming a liquid slag on the surface of the steel and infiltrating between the two surfaces and provides better lubrication granting homogeneous heat transfer along that length of the mould that cannot be achieved through the use of conventional casting oil.

The resulting uniformity from the mould cooling allows a considerable improvement in product quality and generates a strong reduction of distortion in the shape of the billets (rhombohedral):

Benefits:

Operating benefits: