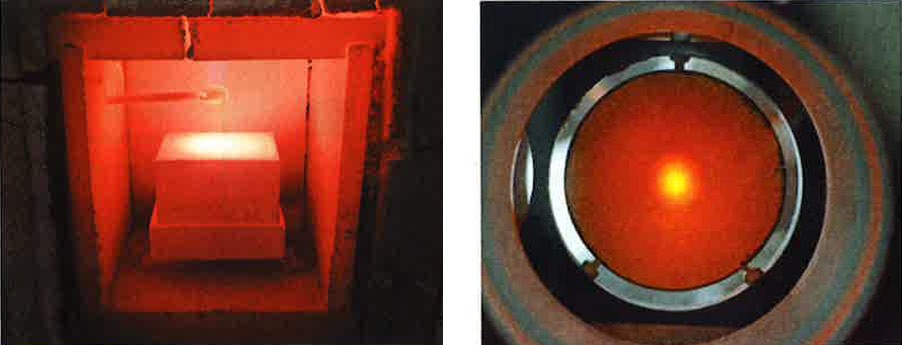

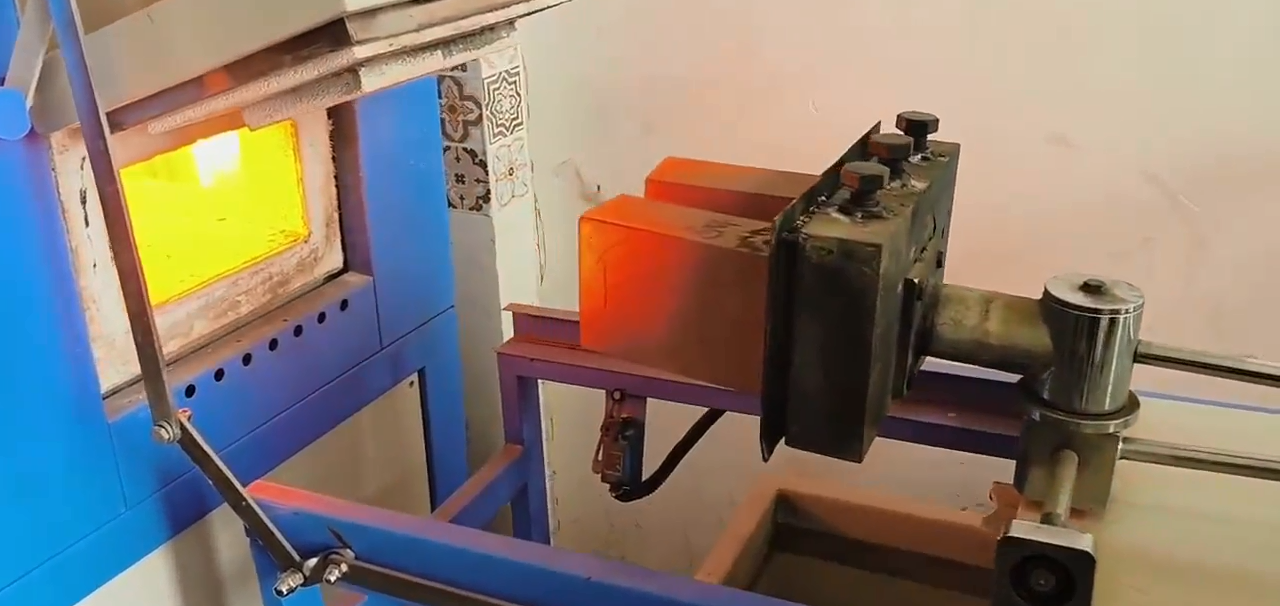

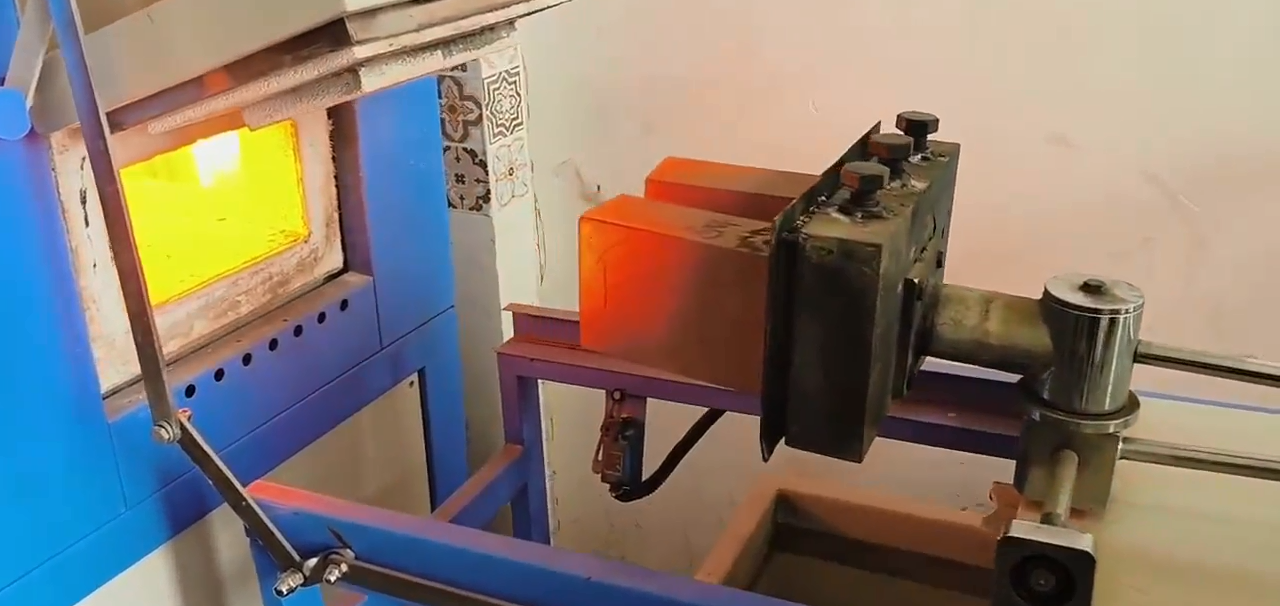

In nearly every high-temperature industry, refractory materials are subjected to rapid and extreme temperature fluctuations. A ladle being filled with molten steel, a furnace door being opened to the cool air, or a rapid heat-up cycle all induce a powerful internal stress known as thermal shock. If a material is not designed to handle this stress, the result is cracking and spalling, which compromises the integrity of the furnace lining and can lead to catastrophic failure.

Optimizing a refractory’s ability to resist thermal shock is therefore a critical aspect of material science and engineering. This involves a holistic approach that considers the material’s inherent chemistry, its internal microstructure, and even its final shape.

Strategy 1: Material Selection – The Chemistry of Expansion

The root cause of thermal shock stress is thermal expansion. When heated, materials expand, and if this happens too quickly, different parts of the material expand at different rates, tearing it apart from the inside. Therefore, the most direct way to improve thermal shock resistance is to choose a material with a very low Coefficient of Thermal Expansion (CTE).

- Prime Examples: Fused Silica is famous for its near-zero thermal expansion, making it exceptionally resistant to thermal shock, though it has limitations at very high temperatures. For broader applications, minerals like Mullite are highly valued for offering an excellent balance of low thermal expansion and great high-temperature strength.

Strategy 2: Engineering the Microstructure

Beyond chemistry, the physical structure of the refractory at a microscopic level plays a huge role in its ability to handle stress.

- Controlled Porosity: While density is often desired for corrosion resistance, a degree of controlled, fine porosity can be beneficial for thermal shock. These microscopic pores can act as “crack arrestors.” When a crack begins to propagate through the material, its energy is dissipated when it reaches a pore, blunting its tip and preventing it from causing a large-scale fracture.

- Toughening Agents: The science of “fracture toughness” involves adding microscopic particles or fibers to the refractory matrix to make it less brittle. The addition of materials like zirconia is a common technique. Zirconia particles can undergo a phase transformation when a crack approaches, which absorbs energy and creates compressive stress that literally squeezes the crack shut.

Strategy 3: Design and Operational Considerations

Finally, how a refractory is shaped and used is critical.

- Product Geometry: Sharp internal corners on a refractory shape act as natural stress concentrators, providing an easy point for cracks to start. Designing custom shapes with smooth, rounded corners helps to distribute thermal stress more evenly.

- Controlled Heating: Even the most shock-resistant material can be broken by abusive operational practices. Adhering to a carefully planned, gradual heat-up schedule is a vital operational procedure for protecting any refractory lining and maximizing its life.

By intelligently combining material selection, microstructure engineering, and smart design, it is possible to create refractory solutions that can reliably withstand the rigors of even the most demanding thermal cycling applications.

Engineered for Thermal Stability

At Pennekamp Middle East, we understand the devastating impact of thermal shock. We provide a wide range of refractory products specifically engineered for high thermal shock resistance, and our technical experts can help you select the right solution for your application.

Contact us today to discuss your thermal cycling challenges and find a refractory solution that delivers reliability and performance.