The global manufacturing sector is experiencing a technological transformation, with innovations reshaping processes across industries. A key element that often goes unnoticed in this evolution is the role of refractory products. These materials, which provide essential protection against extreme temperatures and chemical corrosion, are now being integrated with advanced manufacturing technologies to drive greater efficiency, reliability, and sustainability in high-temperature applications.

The Role of Refractory Products in Modern Manufacturing

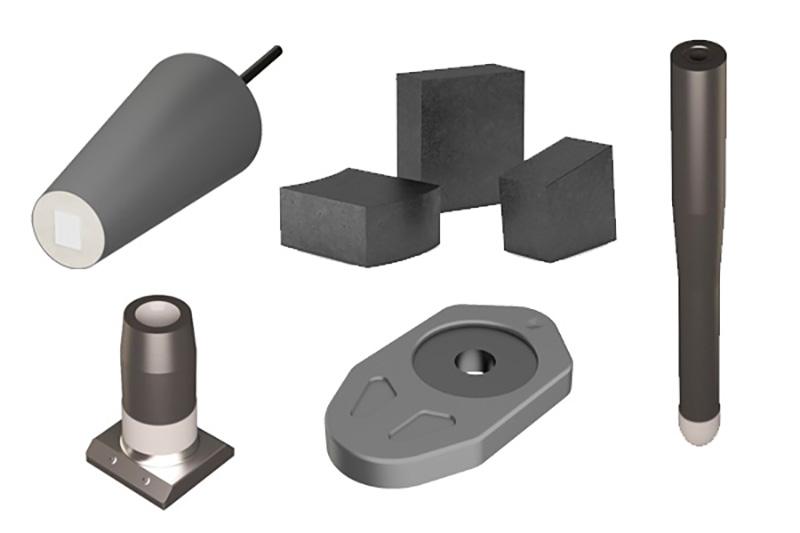

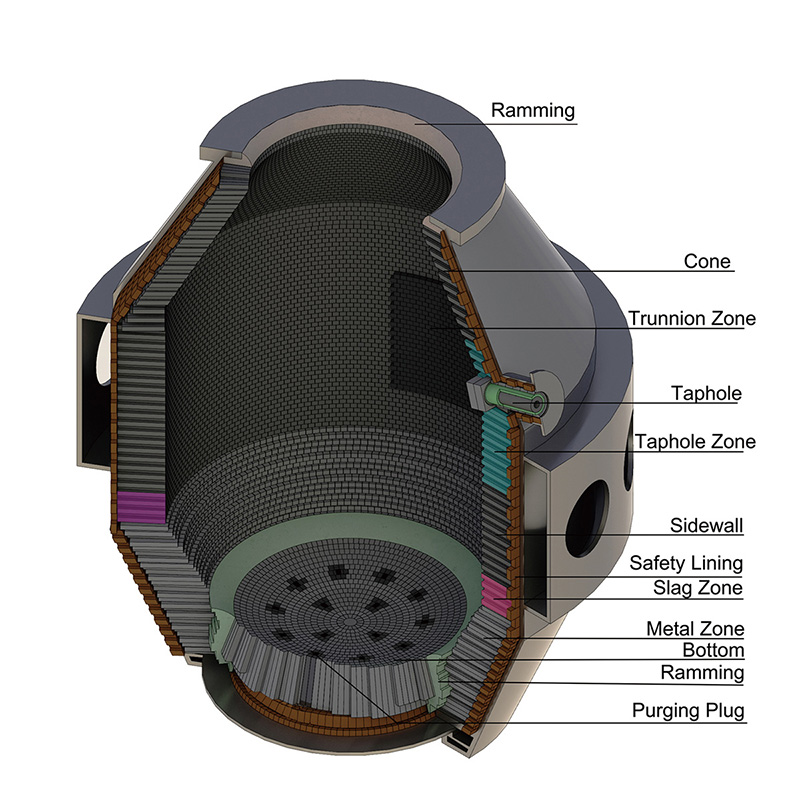

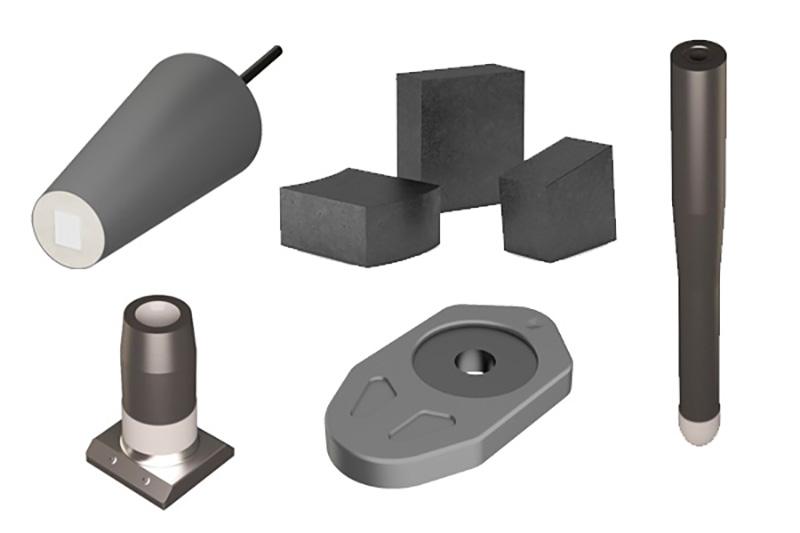

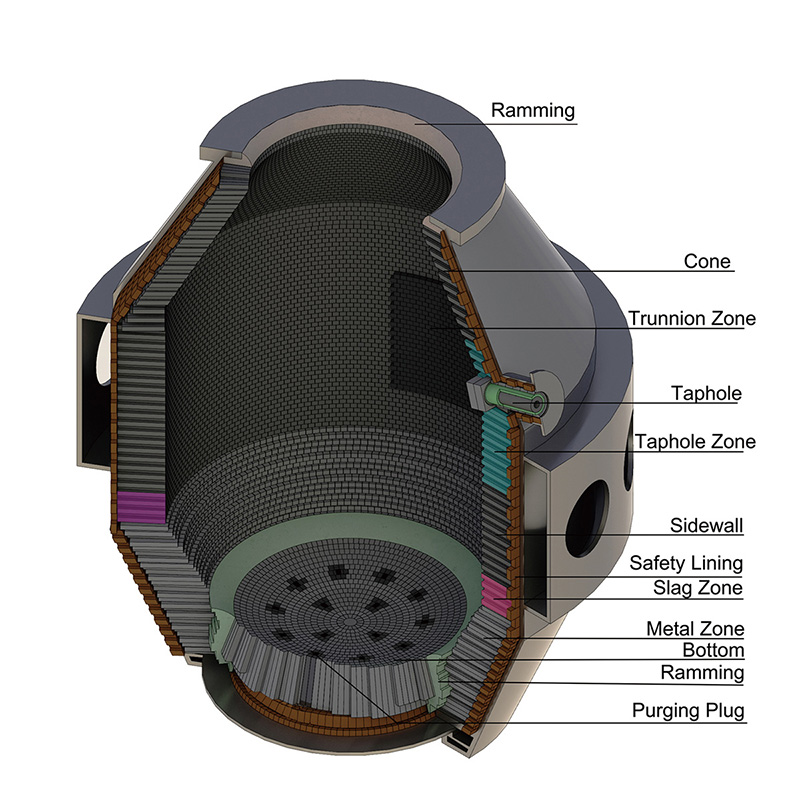

Refractory materials are critical to industries that deal with high-temperature environments, such as steel production, cement manufacturing, and petrochemical refining. They protect critical equipment from thermal wear, corrosion, and mechanical stress. However, with the advent of new manufacturing technologies, the function of refractories is evolving.

Refractory products today are engineered to meet the demands of increasingly complex industrial operations. Their design and performance are now heavily influenced by innovations like automation, data analytics, and additive manufacturing. As a result, refractories are more durable, cost-effective, and optimized for specific applications.

Advances in Manufacturing Technologies and Their Impact on Refractories

- Automation and AI Integration: Automation technologies are revolutionizing how refractory materials are applied in manufacturing. Robotics and artificial intelligence (AI) systems can now accurately apply refractories to furnaces, kilns, and other high-temperature systems with greater precision. This reduces human error and ensures a more consistent application, enhancing operational efficiency.

- Additive Manufacturing: The rise of 3D printing and additive manufacturing has paved the way for more customized refractory solutions. Complex shapes and structures can now be printed with precision, reducing waste and improving the fit of refractory linings. This level of customization allows industries to meet the specific demands of their operations while reducing material costs and improving longevity.

- Data-Driven Optimization: The use of data analytics and sensors has allowed manufacturers to closely monitor the condition of refractory materials in real-time. With predictive maintenance technologies, operators can forecast when refractories will need maintenance or replacement, significantly reducing downtime and optimizing the lifespan of equipment.

Synergy Between Refractories and Advanced Technologies

The synergy between refractory products and advanced manufacturing technologies is enhancing every stage of production—from the design and installation of refractories to their ongoing maintenance and performance optimization. By integrating refractories with advanced technologies, industries are able to achieve higher levels of precision, efficiency, and sustainability.

For example, using data-driven insights, manufacturers can fine-tune the properties of refractory materials to meet the precise conditions of their processes, reducing energy consumption and minimizing waste. In steelmaking, this translates into improved heat retention, better metal quality, and more efficient production cycles.

Moreover, the ability to design and manufacture refractory products with advanced technologies means that industries can achieve more durable, long-lasting solutions, ultimately leading to reduced operational costs.

Conclusion

The evolving relationship between refractory products and advanced manufacturing technologies is a game-changer for industries that rely on high-temperature processes. This synergy not only drives operational efficiency but also promotes sustainability and cost savings. As technology continues to advance, the potential for refractories to play an even more significant role in enhancing manufacturing processes will only grow.

At Pennekamp Middle East, we specialize in providing high-quality refractory raw materials and finished products designed to meet the demands of modern industrial applications. With a focus on innovation and quality, we are committed to supporting your business with the best solutions to optimize performance and efficiency.

Ready to revolutionize your industrial operations with advanced refractory solutions? Contact Pennekamp Middle East today to discover how we can help you achieve greater efficiency, durability, and performance.