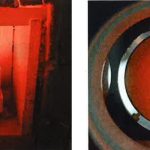

The environment inside a Basic Oxygen Furnace (BOF) is one of the most aggressive in the entire steelmaking industry, characterized by extreme temperatures, violent turbulence, and chemically corrosive slag. While refractory bricks form the primary structure of the lining, advanced monolithic materials like Alumina-Magnesia Ramming Mixes play a crucial role in creating seamless, durable surfaces in critical areas like the furnace bottom.

A ramming mix is a type of unshaped refractory, supplied as a dry powder, that is installed by being densely compacted or “rammed” into place. This method creates a joint-free, monolithic structure. The high performance of alumina-magnesia mixes comes from their specific chemistry, which allows them to form their own protective layer in service.

The Science of Self-Protection: In-Situ Spinel Formation

The key to the performance of these mixes lies in a chemical reaction that occurs at the high temperatures of the BOF. The alumina (Al₂O₃) aggregates and fine magnesia (MgO) powders in the mix react with each other to form a new, extremely strong and stable mineral layer of magnesium aluminate spinel (MgAl₂O₄) at the lining’s hot face.

This “in-situ” formation is critical for two reasons:

- Exceptional Slag Resistance: The newly formed spinel surface is highly resistant to corrosion and penetration by the basic, aggressive slags found in the BOF.

- Densification: The reaction is accompanied by a slight, controlled volume expansion. This expansion helps to close off any remaining porosity in the rammed layer, creating an even denser and more impermeable surface that resists slag infiltration.

Primary Applications in the BOF

The robust nature and installation method of Alumina-Magnesia ramming mixes make them ideal for several applications within the converter:

- Converter Bottoms: A primary use is for installing the seamless working layer of the furnace bottom, creating a durable foundation that can withstand the impact of scrap charging and the turbulent steel bath.

- Hot and Cold Repairs: Their versatility makes them an excellent choice for patching localized areas of wear, helping to extend the overall campaign life of the furnace lining.

- Tap Hole Maintenance: They can be used to form and repair the area around the tap hole, ensuring a durable and safe tapping block.

By combining the installation advantage of a monolithic material with the advanced science of in-situ spinel formation, these ramming mixes offer a versatile and high-performance solution for maintaining the integrity of the BOF lining.

Engineered Mixes for BOF Reliability

At Pennekamp Middle East, we provide a range of high-quality monolithic refractories, including expertly formulated Alumina-Magnesia ramming mixes for BOF applications. Our products are designed to deliver exceptional durability and slag resistance in the toughest steelmaking conditions.

Contact our technical team today to find the right ramming mix for your converter maintenance needs.