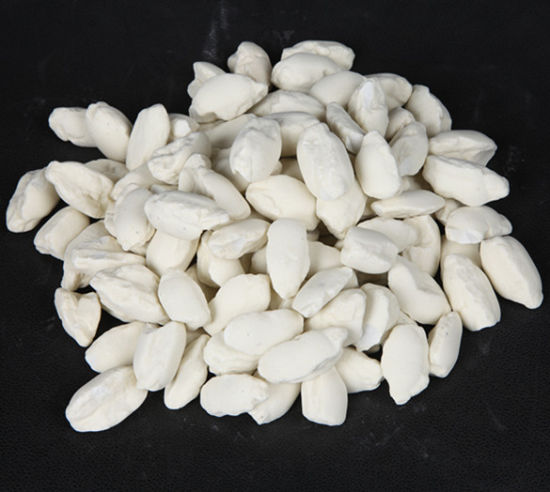

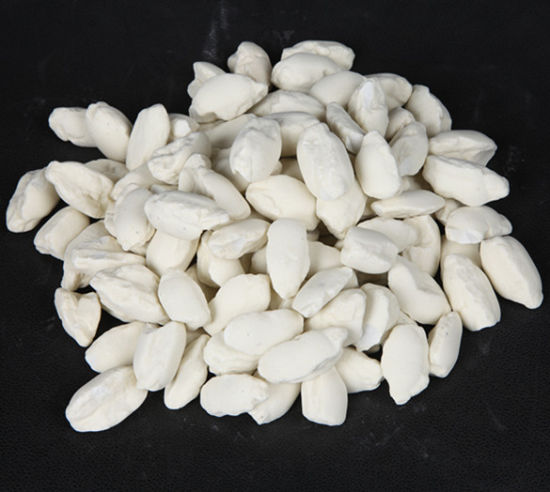

In the pursuit of creating more durable and reliable refractory products, material science often turns to advanced, synthetically produced minerals. Among these, Sintered Spinel (Magnesium Aluminate Spinel, MgAl₂O₄) stands out as a high-performance solution, engineered specifically to withstand the dual challenges of extreme heat and aggressive chemical attack.

Unlike its fused counterpart, Sintered Spinel is not melted. Instead, it is produced by mixing high-purity, fine-grained magnesia and alumina powders, which are then fired at very high temperatures (typically over 1700°C) but below their fusion point. This sintering process encourages the solid-state diffusion of the raw materials, forming a dense, stable spinel with a unique, well-developed crystal structure. This controlled microstructure is the key to its exceptional performance.

Key Properties Forged Through Sintering

The unique manufacturing process of Sintered Spinel imparts a set of properties that make it highly valuable for critical refractory applications.

- Excellent Thermal Shock Resistance: The well-developed crystal structure and controlled microstructure of Sintered Spinel allow it to absorb the stresses induced by rapid temperature changes. This property is crucial in applications with frequent thermal cycling, significantly reducing the risk of cracking and spalling1.

- Superior Slag Resistance: Sintered Spinel exhibits excellent resistance to corrosion and penetration by basic slags, particularly those found in steelmaking processes. Its stable chemical nature prevents the destructive reactions that can quickly degrade other refractory materials2.

- High Refractoriness and Hot Strength: With a high melting point and excellent strength at elevated temperatures, Sintered Spinel maintains its structural integrity in the most demanding industrial environments.

- Low Thermal Expansion: Its coefficient of thermal expansion is relatively low, which further contributes to its outstanding thermal stability and resistance to spalling.

Primary Applications in High-Temperature Industries

The robust properties of Sintered Spinel make it the material of choice for refractories used in the most aggressive zones of industrial processes.

- Steel Industry: It is a key component in high-performance refractory bricks and castables used in steel ladles, particularly in the slag line where the environment is most corrosive. It is also used in slide gate plates and other flow control systems where thermal stability is paramount.

- Cement Industry: Sintered Spinel is used to produce durable refractory bricks for the burning zone of cement rotary kilns, where it must withstand extreme heat, abrasion, and chemical attack from the clinker and process gases3.

In essence, Sintered Spinel is more than just a raw material; it is an engineered solution that enhances the performance, lifespan, and safety of critical refractory linings.

Leverage the Power of Advanced Materials with Pennekamp

At Pennekamp Middle East, our comprehensive portfolio includes a full range of advanced refractory raw materials, including high-quality Sintered Spinel. We provide the essential building blocks that enable our clients to manufacture superior refractory products for the most demanding applications.

Contact us today to learn more about our Sintered Spinel offerings and how our expertise in raw materials can elevate your product performance.