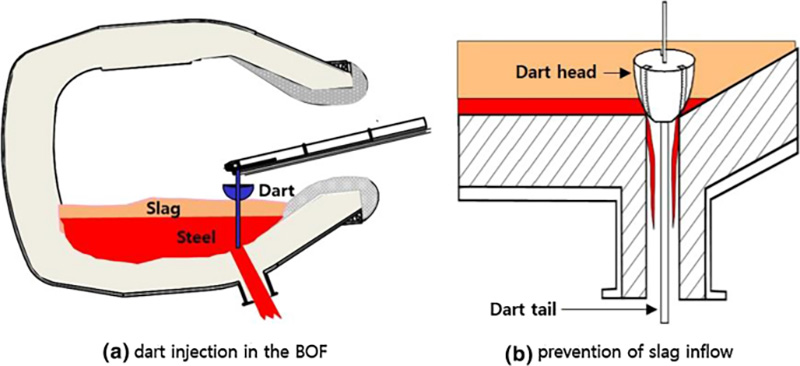

In the demanding world of steelmaking, optimizing every element of the process is key to improving efficiency and ensuring quality. One crucial component in controlling the steelmaking process is the BOF (Basic Oxygen Furnace) slag limiting dart, which helps to regulate the flow of molten metal and slag. However, to ensure its effectiveness, these darts need to be made from high-quality refractories that can withstand the harsh conditions inside the furnace.

What Are BOF Slag Limiting Darts?

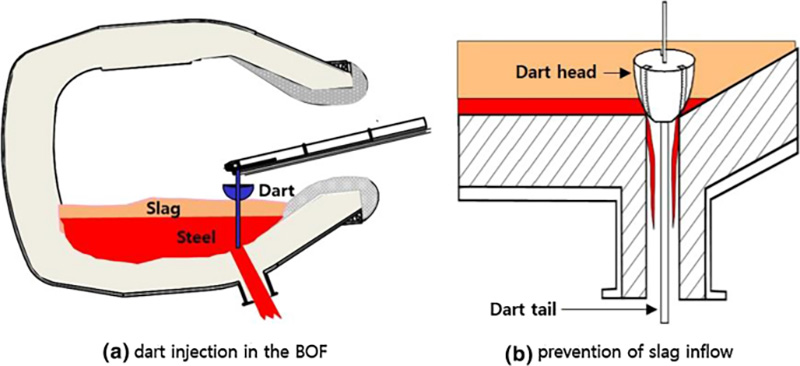

BOF slag limiting darts are specialized components used in the Basic Oxygen Furnace, designed to limit the flow of slag while ensuring that the molten steel remains uncontaminated during the conversion process. These darts play a pivotal role in controlling the chemical composition of the steel, preventing excessive slag formation, and maintaining a smooth flow of molten metal.

However, the slag limiting darts face extreme conditions, including high temperatures, corrosive slags, and mechanical wear. Therefore, using high-performance refractories in their construction is essential to ensure long-lasting durability and reliable performance.

Why Refractories Matter for Slag Limiting Darts

Refractories play a vital role in the performance of slag limiting darts, as they provide the necessary protection against extreme temperatures and the corrosive nature of molten slag. The right refractory materials used in the darts ensure that they can endure the harsh furnace conditions and contribute to improved steelmaking efficiency.

Here are the key benefits of using high-quality refractories for BOF slag limiting darts:

- Enhanced Durability: The refractory materials used in slag limiting darts are designed to withstand the severe wear caused by repeated exposure to molten metal and slag. This results in reduced maintenance needs and a longer lifespan of the dart components.

- Slag Resistance: Steelmaking processes often involve highly corrosive slags that can quickly degrade non-refractory materials. The right refractories are resistant to slag attack, ensuring the dart remains intact and functional throughout the process.

- Thermal Stability: Refractories used in slag limiting darts need to perform under extreme temperature conditions. High thermal stability allows the dart to maintain its structural integrity, even in the hottest areas of the furnace, improving overall process control.

- Reduced Downtime: By using high-performance refractories, steelmakers can minimize the frequency of dart replacements, leading to fewer production interruptions and more consistent steel output. This results in increased operational efficiency and cost savings.

Pennekamp Middle East’s Refractory Solutions for BOF Slag Limiting Darts

At Pennekamp Middle East, we specialize in providing top-quality refractory solutions that meet the demanding needs of BOF slag limiting darts. Our refractories are engineered to withstand the intense heat, chemical attack, and mechanical stresses inside the furnace, ensuring longer-lasting and more reliable performance.

By choosing Pennekamp Middle East, steelmakers benefit from:

- Customized Solutions: Our refractories are tailored to the specific needs of each steelmaking operation, ensuring optimal performance in every furnace.

- Long-Term Durability: Our high-quality materials minimize wear, extending the lifespan of dart components and reducing operational downtime.

- Enhanced Efficiency: Our products contribute to smoother, more efficient steelmaking processes, ultimately improving the quality of the final product.

Conclusion

BOF slag limiting darts are crucial components in ensuring the efficient flow of molten metal and slag during steelmaking. By using advanced refractory materials designed for extreme conditions, steelmakers can enhance the durability, performance, and efficiency of these darts.

At Pennekamp Middle East, we provide high-performance refractories that are tailored to meet the specific needs of your steelmaking operations. With our expertise, we can help you improve the reliability and efficiency of your process while reducing downtime and costs.

Contact Pennekamp Middle East today to learn more about our refractory solutions for BOF slag limiting darts and optimize your steelmaking processes.